Tank heads are used as endcaps on cylindrical tanks, drive cylinders, distillation towers, reactors, gas storage tanks, and more. Tank heads often adhere to ASME standards or other comparable codes. Tank heads are crucial pressure vessel structural components that can hold dangerous or extremely volatile compounds. The integrity of the tank and tank head is preserved through correct design and construction. Read More…

Century Metal Spinning provides high-quality aluminum & stainless steel metal spinning. Products can also be spun from titanium, copper, silver, gold & other materials. Examples of our products include rings, spheres, tubes, cylinders & tank heads. With our ISO 9001 & AS9100 certifications, we proudly serve aerospace, electronics, marine, military, pharmaceutical and a number of other industries.

Kryton Engineered Metals seamlessly crafts fabricated products. We are an ISO 9001:2015, full-service metal fab and spinning manufacturer with deep experience in air movement, lighting, vacuum, medical, food and beverage, agriculture, high voltage, and other markets. Kryton is consistently investing in new processes and equipment to grow with our expanding customer base. From a single piece to ...

At Elemet Group, our expertise revolves around providing comprehensive solutions in metal spinning, serving the diverse needs of clients across various industries. With decades of combined experience, a dedication to quality, and a customer-centric approach, we have positioned ourselves as a trusted leader in the field of metal forming. Our primary focus is on delivering a wide range of...

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

At Tallmadge Spinning & Metal Co., our expertise centers around providing comprehensive solutions in metal spinning, catering to the diverse needs of clients across various industries. With decades of collective experience and a steadfast commitment to excellence, we've positioned ourselves as a trusted leader in the metal forming industry. Our primary focus is on delivering a broad range of...

More Tank Head Companies

Tank heads are frequently coated, heat-treated, or constructed with stainless steel.

Types of Tank Heads

Hemispherical heads

A spherical shape is optimal for a tank head because the stresses are properly distributed through the skull’s material. The radius of the cylindrical portion of the vessel mirrors the radius of the head. Due to their perfect form, hemispherical heads are a common choice for pressure vessels. Hemispherical heads are used on liquid and gas storage tanks and are known as ‘dish ends.’ It has a larger maximum radial section and, therefore a maximum pressure distribution area because of this.

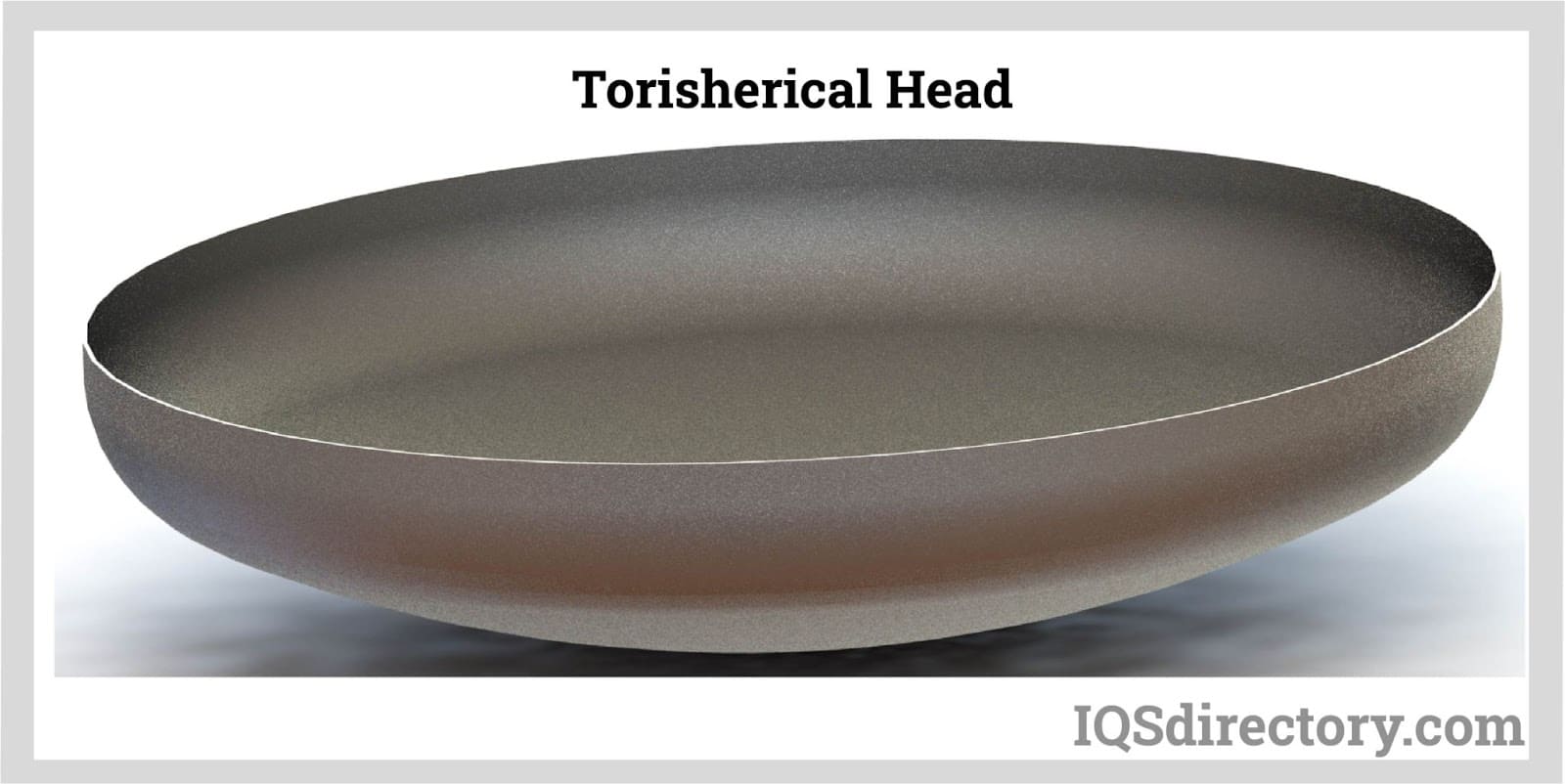

Torispherical Tank Heads

Torispherical heads are semi-hemispherical domes with a knuckle and a straight flange at the base. These are the pressure vessel heads used the most. They have a larger radial section than ellipsoidal heads to distribute pressure more evenly and endure maximum pressure. Torispherical heads are more expensive but save time to use.

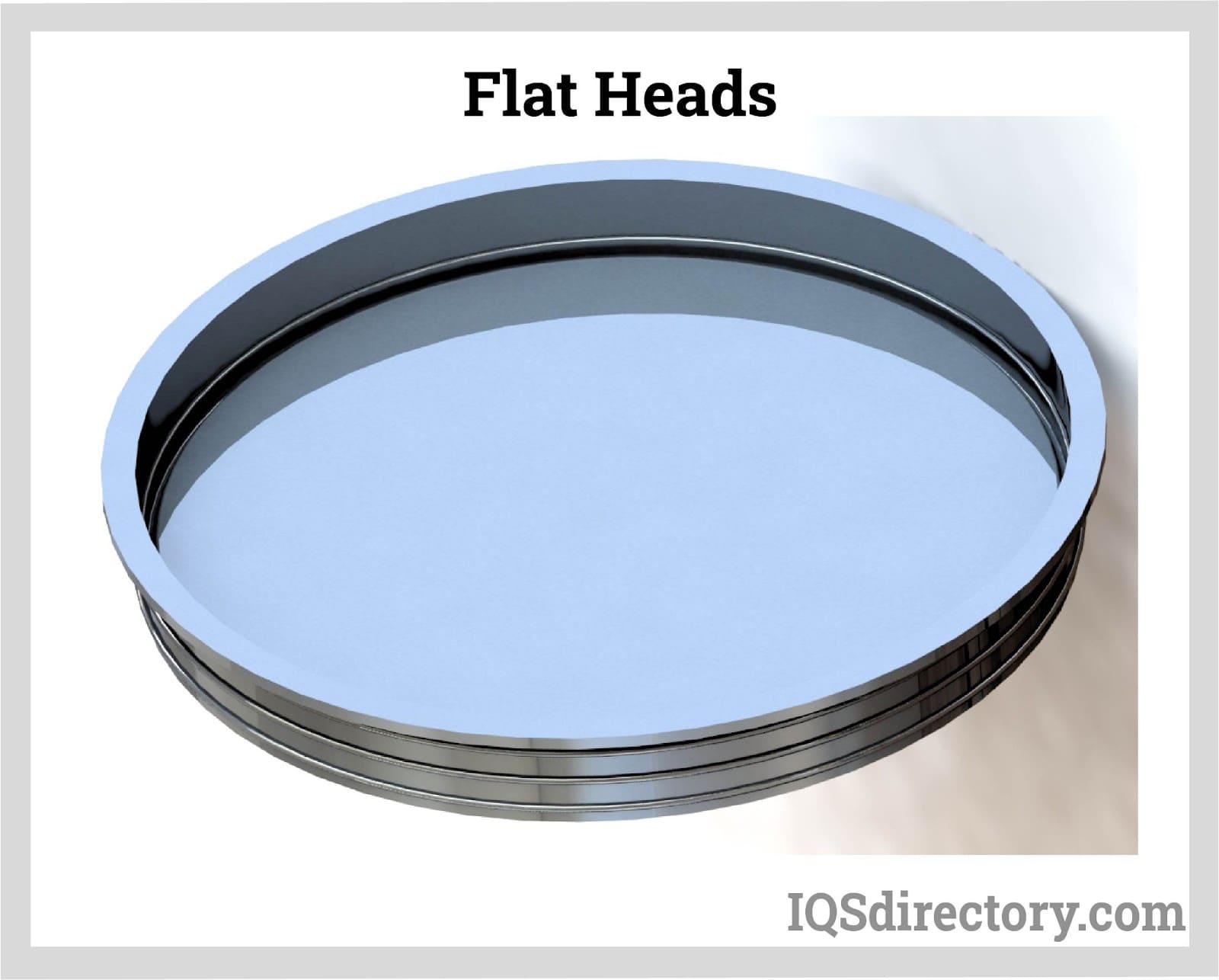

Flat Heads

Flat and flat-sloping heads are simple to construct but sacrifice sturdiness. They are used in vessels with smaller diameters in low-pressure applications and built flush to the container’s surface. Flat heads have a lower capacity to withstand pressure. In addition, the flat area receives the most radiation, making it uneconomical.

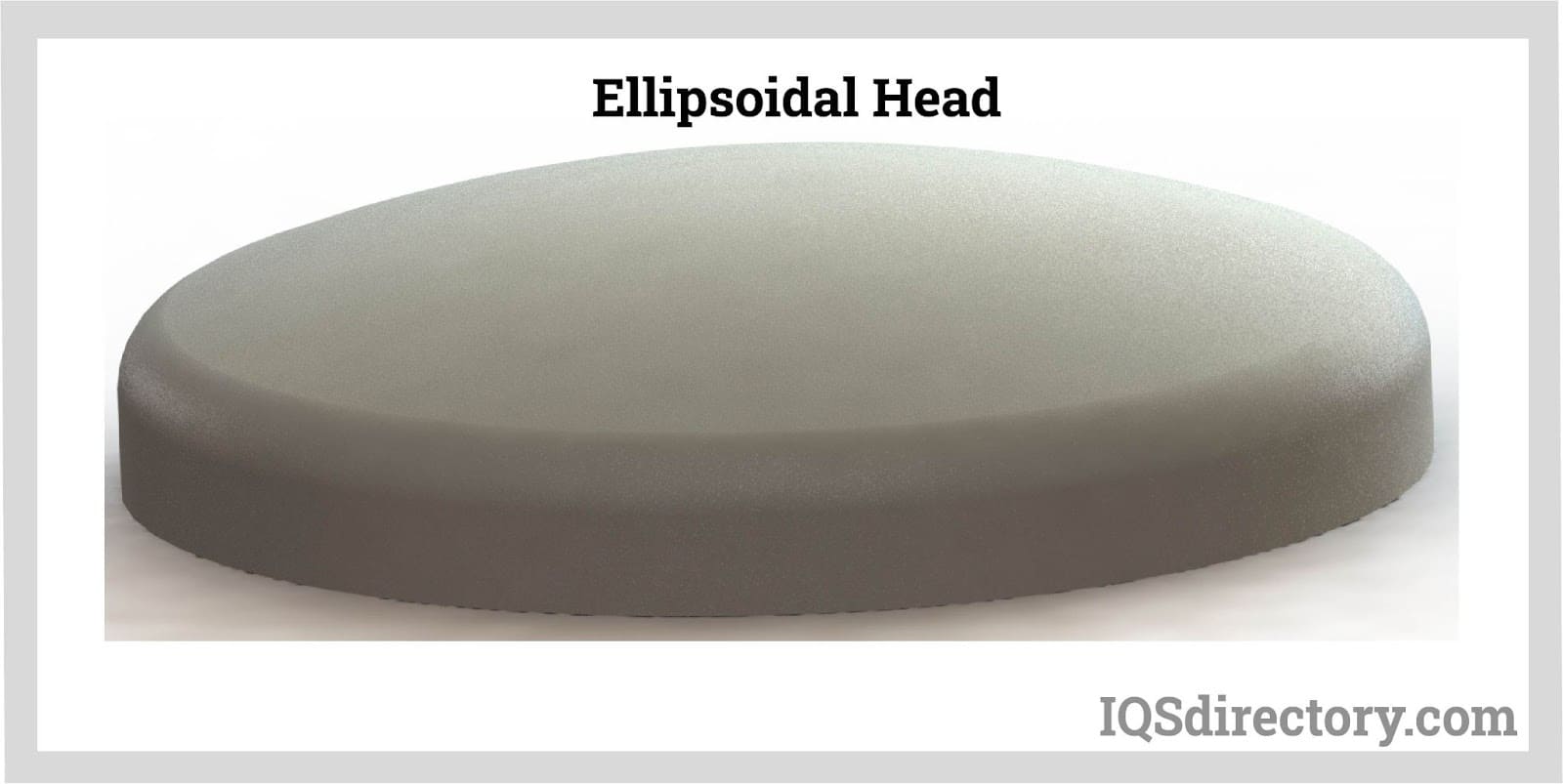

Ellipsoidal heads

Ellipsoidal (or elliptical) heads are more cost-effective because their height only accounts for a small portion of their circumference. Compared to tropospheric heads, semi-ellipsoidal dished heads are deeper and stronger. They cost more to produce, but they are stronger and more pressure-resistant.

Ellipsoidal heads still have a square flange and a knuckle. Since the pressure is not distributed as uniformly as in a torispherical head, the elliptical design is not as strong. Nevertheless, it is a popular option because it can withstand the most pressure.

Toriconical heads

Toriconical heads have a wide base at the shell and a tapering head shaped like concentric cones. At the wide end of the cone, toriconical heads feature a knuckle and a straight flange. They are more hygienic than concentric cones, although they cost more to produce.

Applications and Benefits of Tank Heads

- Pressure autoclaves in the medical profession can use tank heads.

- Tank heads can be used in petroleum tanks and water tanks.

- Tank heads prevent spills and contents loss.

- Compressors and refrigerants also use tank heads to store liquid gas.

- Tank heads can reduce expenses if they are used properly.

- Tank heads guarantee the security of employees and equipment.

Choosing the Correct Tank Head Supplier

To ensure you have the most positive outcome when purchasing a tank head from a tank head supplier, it is important to compare several companies using our directory of tank head suppliers. Each tank head supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each tank head business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple tank head suppliers with the same form.

Cold Headed Parts

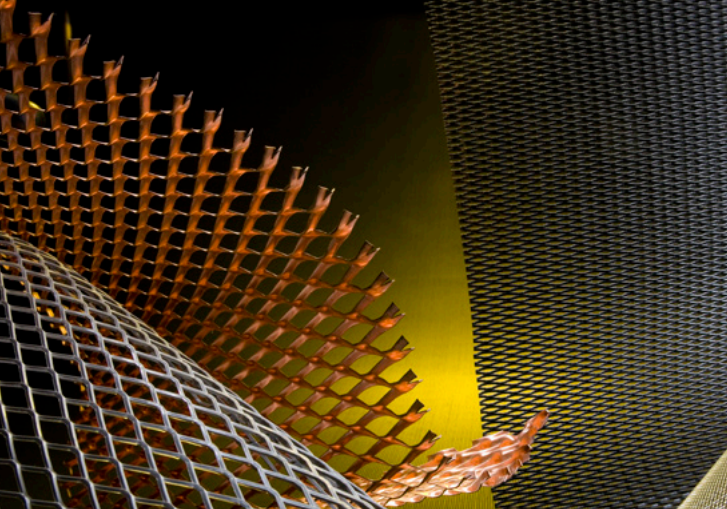

Cold Headed Parts Expanded Metals

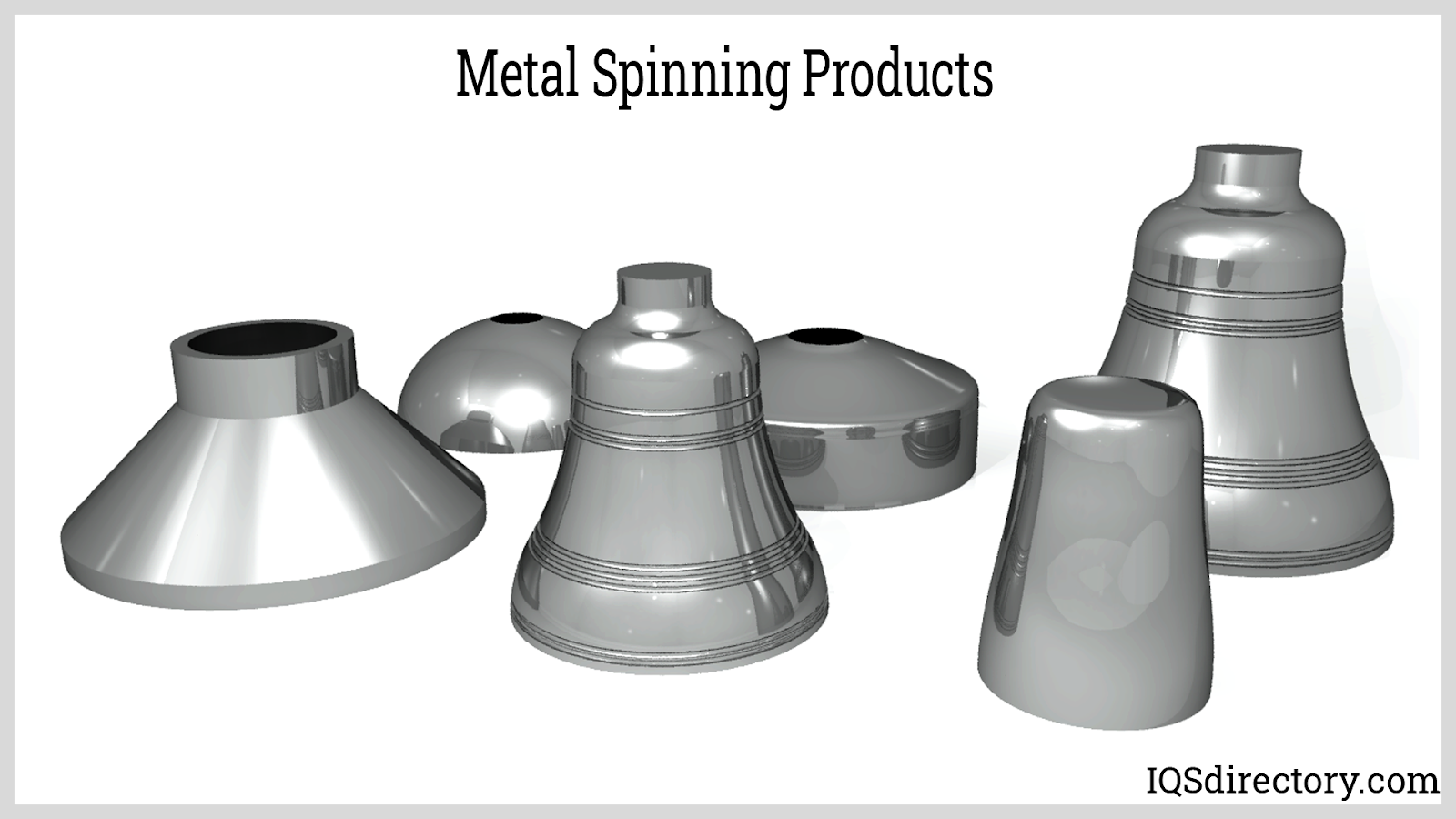

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

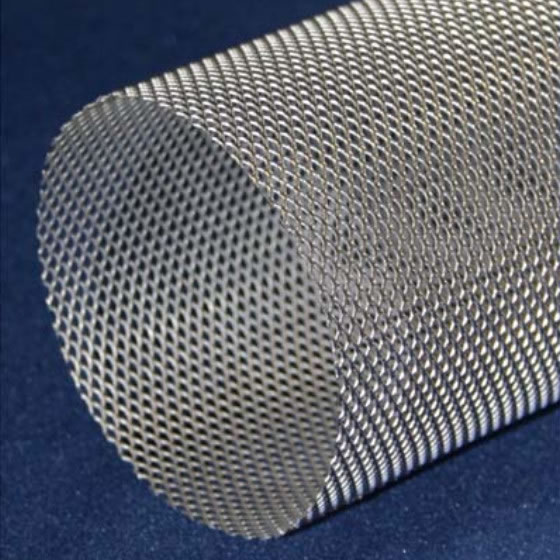

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services