The technique of sheet metal spinning, also known as metal spinning or spin forming, involves rotating a sheet of metal while exerting forces on it to shape it into a cylindrical object. Read More…

Century Metal Spinning provides high-quality aluminum & stainless steel metal spinning. Products can also be spun from titanium, copper, silver, gold & other materials. Examples of our products include rings, spheres, tubes, cylinders & tank heads. With our ISO 9001 & AS9100 certifications, we proudly serve aerospace, electronics, marine, military, pharmaceutical and a number of other industries.

Kryton Engineered Metals seamlessly crafts fabricated products. We are an ISO 9001:2015, full-service metal fab and spinning manufacturer with deep experience in air movement, lighting, vacuum, medical, food and beverage, agriculture, high voltage, and other markets. Kryton is consistently investing in new processes and equipment to grow with our expanding customer base. From a single piece to ...

At Elemet Group, our expertise revolves around providing comprehensive solutions in metal spinning, serving the diverse needs of clients across various industries. With decades of combined experience, a dedication to quality, and a customer-centric approach, we have positioned ourselves as a trusted leader in the field of metal forming. Our primary focus is on delivering a wide range of...

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

At Tallmadge Spinning & Metal Co., our expertise centers around providing comprehensive solutions in metal spinning, catering to the diverse needs of clients across various industries. With decades of collective experience and a steadfast commitment to excellence, we've positioned ourselves as a trusted leader in the metal forming industry. Our primary focus is on delivering a broad range of...

More Spin Forming Companies

The spinning of sheet metal includes the application of pressures to shape the sheet metal; no material is removed during the process.

How Sheet Metal Spinning is Performed

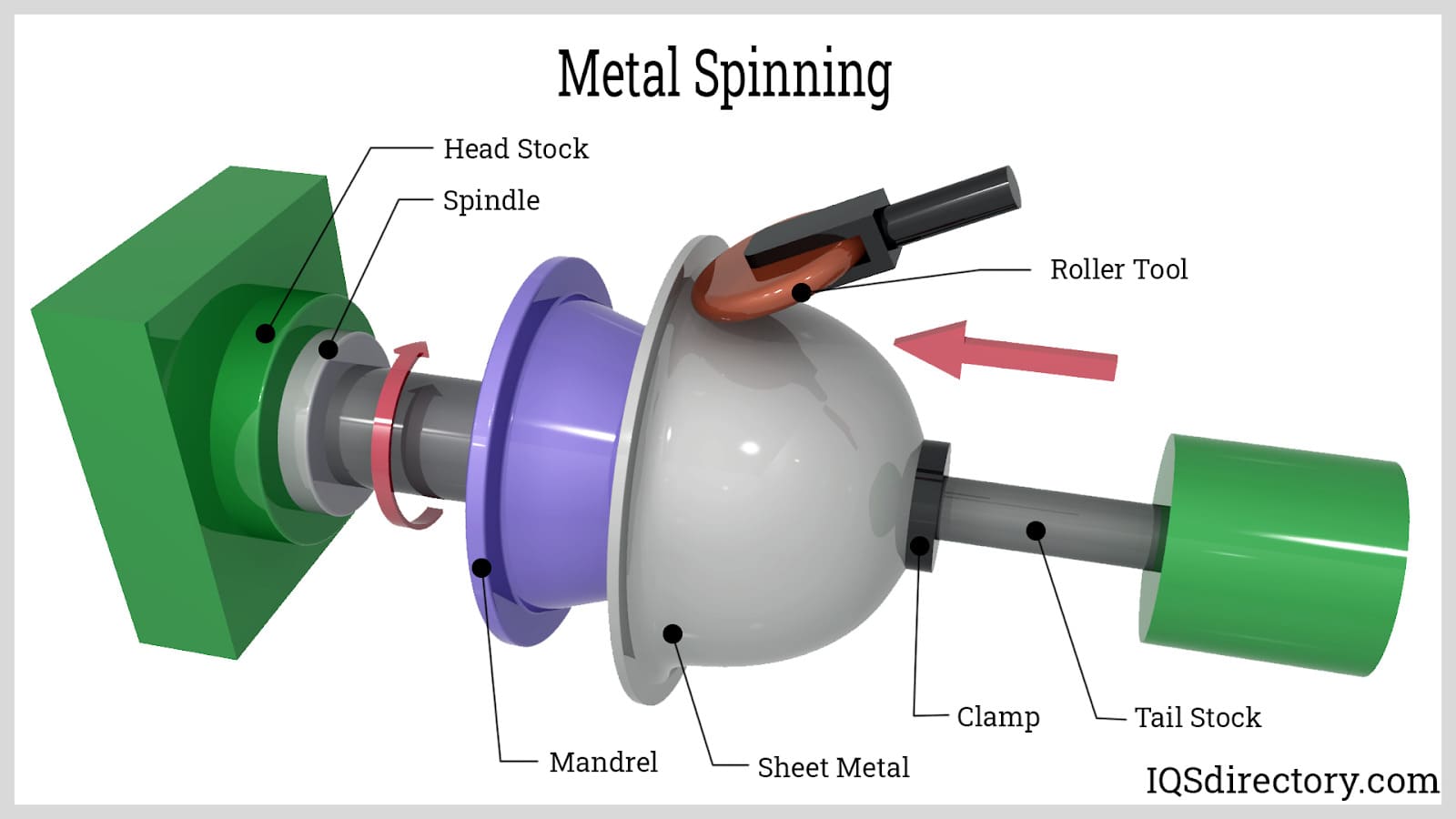

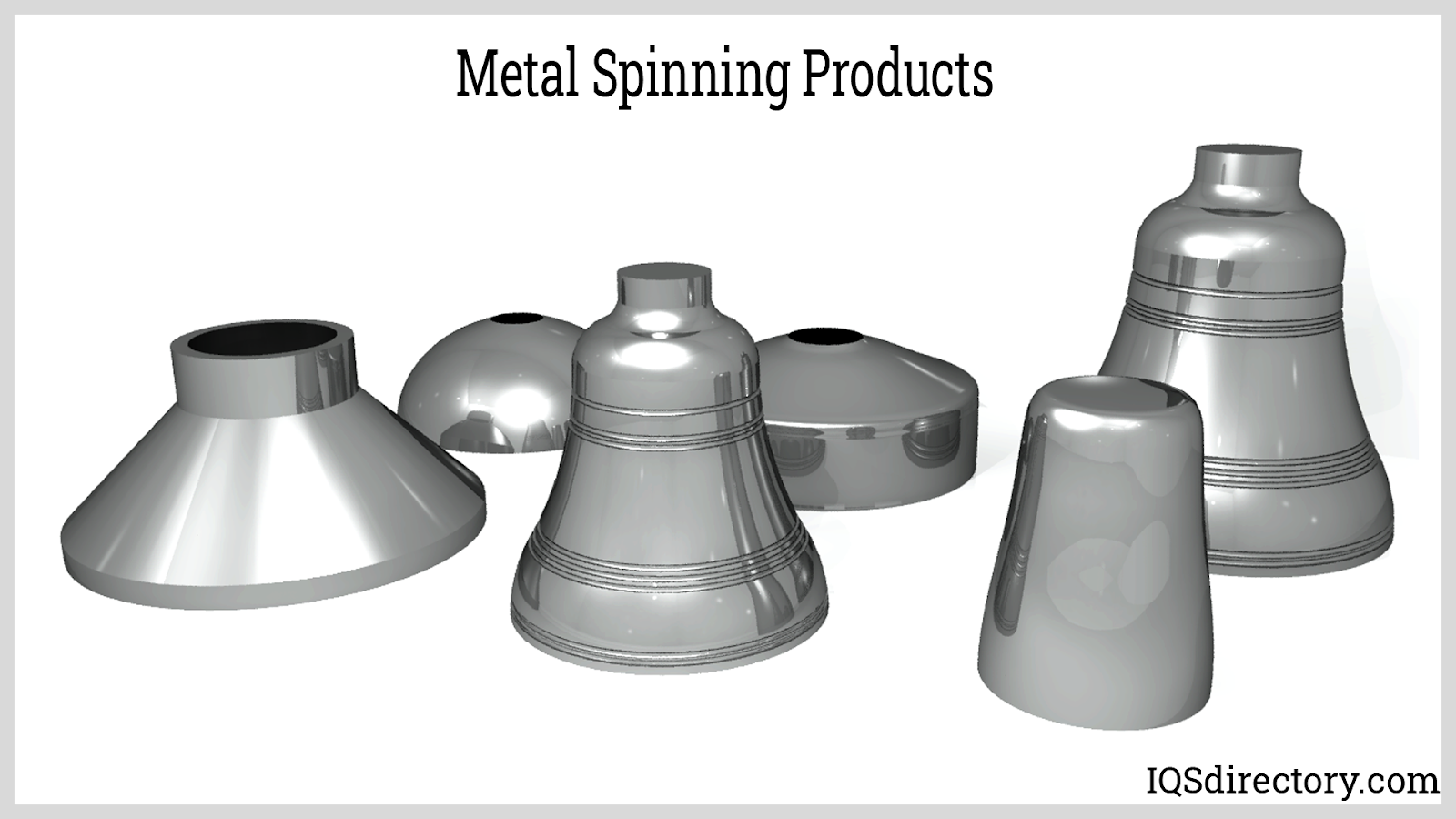

In a sheet metal spinning operation, the metal piece is quickly turned while being forced against rollers. The mandrel supporting the sheet metal causes it to take the shape of the mandrel when it is pressed by the rollers, giving the desired shape. The components created by spinning sheet metal exhibit rotational symmetry; most are hollow-shaped (like a cylinder, hemisphere, or cone). A manual lathe or CNC lathe is typically used for sheet metal spin forming. The blank, mandrel, roller, and a spinning machine tool are the important primary elements throughout the metal spinning process (i.e., manual or CNC lathe).

A sheet of metal in the shape of a disk is cut out of the stock and used as the spinning blank. A mandrel is a sturdy object that aids in giving the desired shape to the blank sheet when pressed with a roller. And the rotating chuck of the lathe is joined with this mandrel. There are several types of mandrels for varied uses, but multi-piece mandrels are employed in sheet metal spinning, especially for spinning complex pieces. A wooden mandrel or a plastic mandrel may be utilized because the spinning process does not subject the mandrel to much wear.

But the metal mandrel is favored for purposes of large-scale manufacture. The lathe's headstock and tailstock are secured together with the sheet metal blank and mandrel, and the lathe is then rotated rapidly. With a roller tool, force is provided during the rotation of these components, pressing the sheet metal and causing it to bend and take the shape of the mandrel. The final shape is achieved by repeatedly passing the roller tool over sheets with thicker or more intricate shapes. Typically, steel or brass rollers attached to a lever press a metal sheet. The spinning rollers are inexpensive and seldom worn out during spin forming.

Spin Forming Methods

There are four main spinning techniques utilized in spin forming.

- Conventional Spinning

- Shear Spinning

- Cold Spinning

- Hot Spinning

Conventional Spinning

Conventional spinning involves pushing the blank up against the mandrel, giving it its shape. Therefore, the completed component will resemble a mandrel in shape and have a diameter less than the blank. Additionally, the spinner component's thickness will remain consistent.

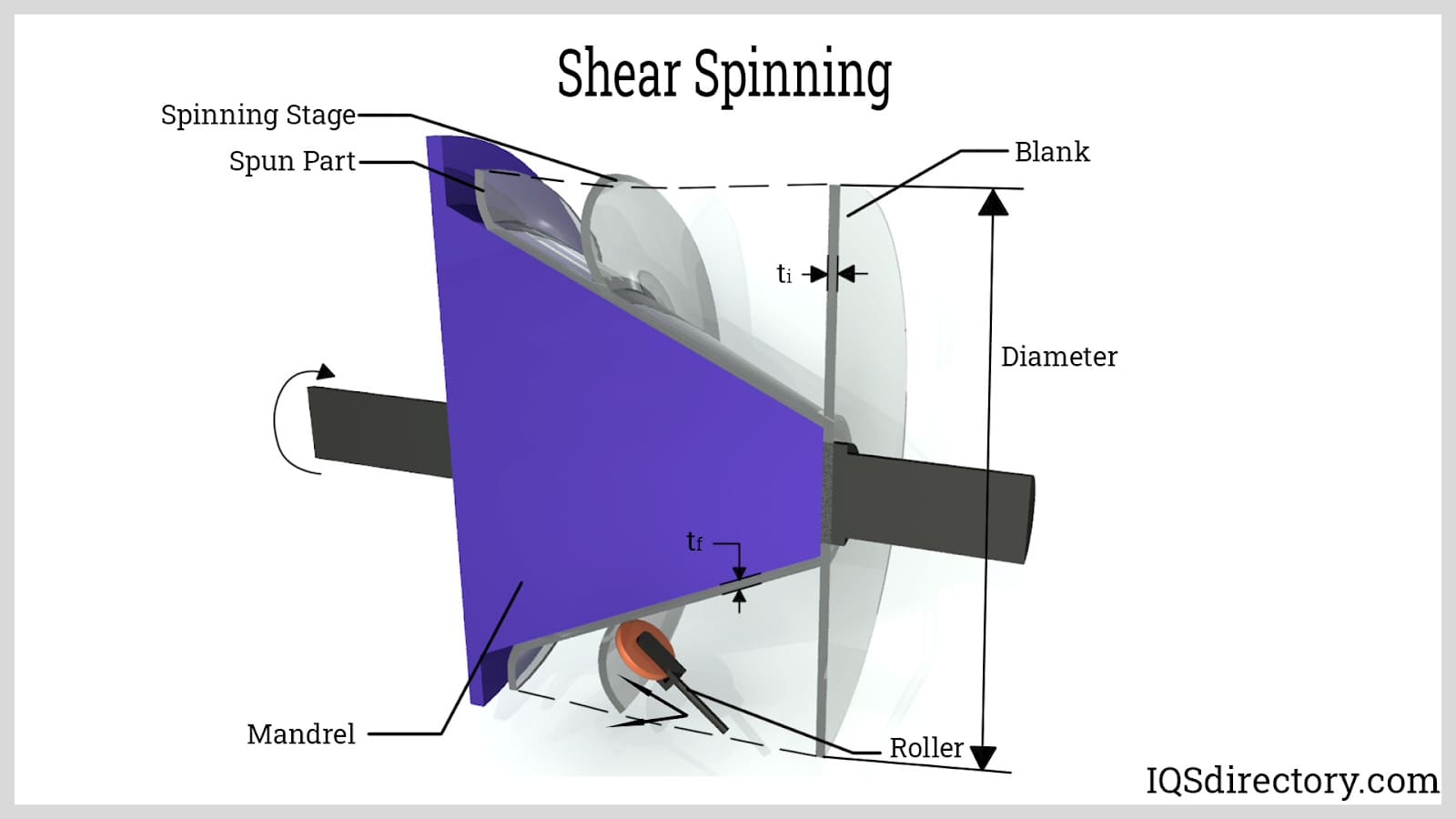

Shear Spinning

In shear spinning, the roller moves forward while bending the sheet blank over the mandrel and applying downward stress. As a result, the thickness of the spinned component will decrease as the sheet blank stretches. With shear spinning, the spinned part's outside diameter maintains its initial blank diameter.

Types of Spinning Processes

Depending on whether the blank or workpiece has been heated before spinning, the spinning process is divided into two categories: hot-spinning and cold-spinning.

Hot Spinning

The metal blank is heated to the forging temperature and then formed into the required shape during hot spinning. It is done by pressing metal over the forming mandrel using a blunt tool that makes contact with the rotating part's surface. This technique is typically utilized for thicker plates and sheets that cannot be deformed plastically by a pressing instrument at room temperature. In addition, backup support opposite the tool is utilized when dealing with relatively thin sheets to prevent creasing at the outer edge. The hot spinning creates components like the heads for huge tanks, refinery equipment, and pressure vessel vessels.

Cold Spinning

The difference between the cold and hot spinning processes is that the metal blank is handled at room temperature. Thin aluminum plates, sheets, and other soft metals are typically the ideal candidates for this technique. In addition, light reflectors, culinary utensils, liquid containers, radial engine cowlings, hollow domestic parts, and other items are produced via cold spinning.

Advantages of Spinning

When several different forms are required, but only a small number of each shape is needed, the spinning technique is typically utilized to manufacture huge pieces. Some advantages are listed below.

- Comparable to Drawing Process: Spinning is similar to drawing when making cylindrical, axisymmetric pieces.

- Economic process: Spinning requires a few basic tools, so tiny lots may afford it.

- Suitable for Large Parts: Spinning makes larger pieces much easier to create than sketching.

- Complicated Shapes Produced: The spinning method makes it simple to create complex shapes.

- No Investment in Die Making: Since no unique tooling or dies are needed to be made, the spinning action can be quickly tested without spending money on new models.

- No Finishing Operation Required: The spun parts don't need finishing processes, such as bending, trimming, etc.

Limitations of Spinning

- More Time Required: The spinning process takes longer than the drawing procedure to make a cup.

- More Skill Required: The tool must be manually forced on the metal blank during the spinning process, so operator expertise is more important.

- Not Suitable for Large-Scale Production: Large-scale production is not a good fit for the spinning process because it takes more time.

Applications of Spinning

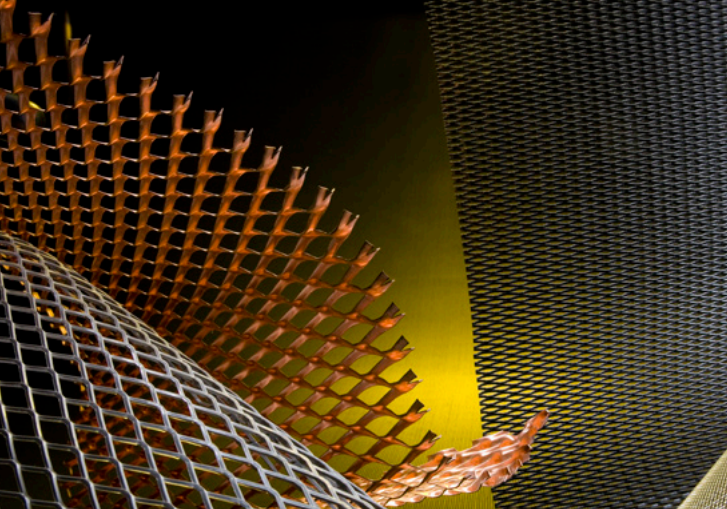

The majority of metals that come in sheets can be spun. Carbon steel, aluminum, copper, brass, and stainless steel are the most frequently utilized materials.

- Alloys made of molybdenum, titanium, and magnesium are often spun using a heated process.

- It is simple to hand spin aluminum alloy to a thickness of 6 mm, low carbon steels and brass up to 4.5 mm thick, and stainless steel up to 3 mm thick.

- Axis-symmetrical cup-shaped products are made using the spinning technique.

- When the expense of the necessary instruments makes a drawing technique unprofitable, a small batch of products is produced using the spinning method.

- Making deep conical pieces is especially suited for spinning.

- The only method for creating many intricate objects and re-entrant shapes is spinning.

- Additionally, hollow items with a neck diameter that is smaller than the midsection can be produced by spinning.

Choosing the Right Spinning Manufacturer

To make sure you have the most positive outcome when purchasing Spinning from a Spinning Manufacturer, it is important to compare at least 4 Companies using our Spinning directory. Each Spinning Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Spinning business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Spinning companies with the same form.

Cold Headed Parts

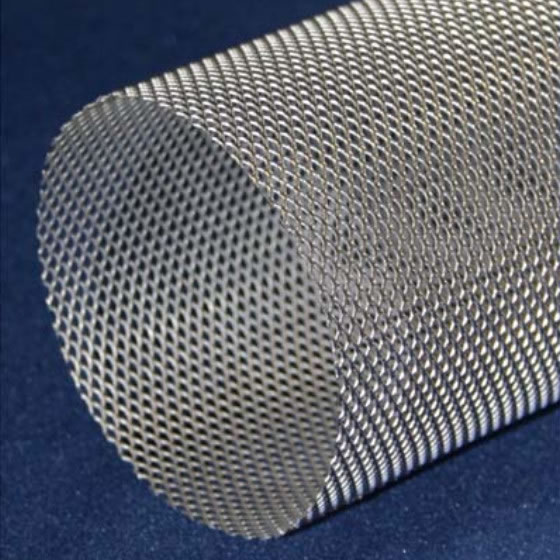

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

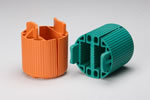

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services