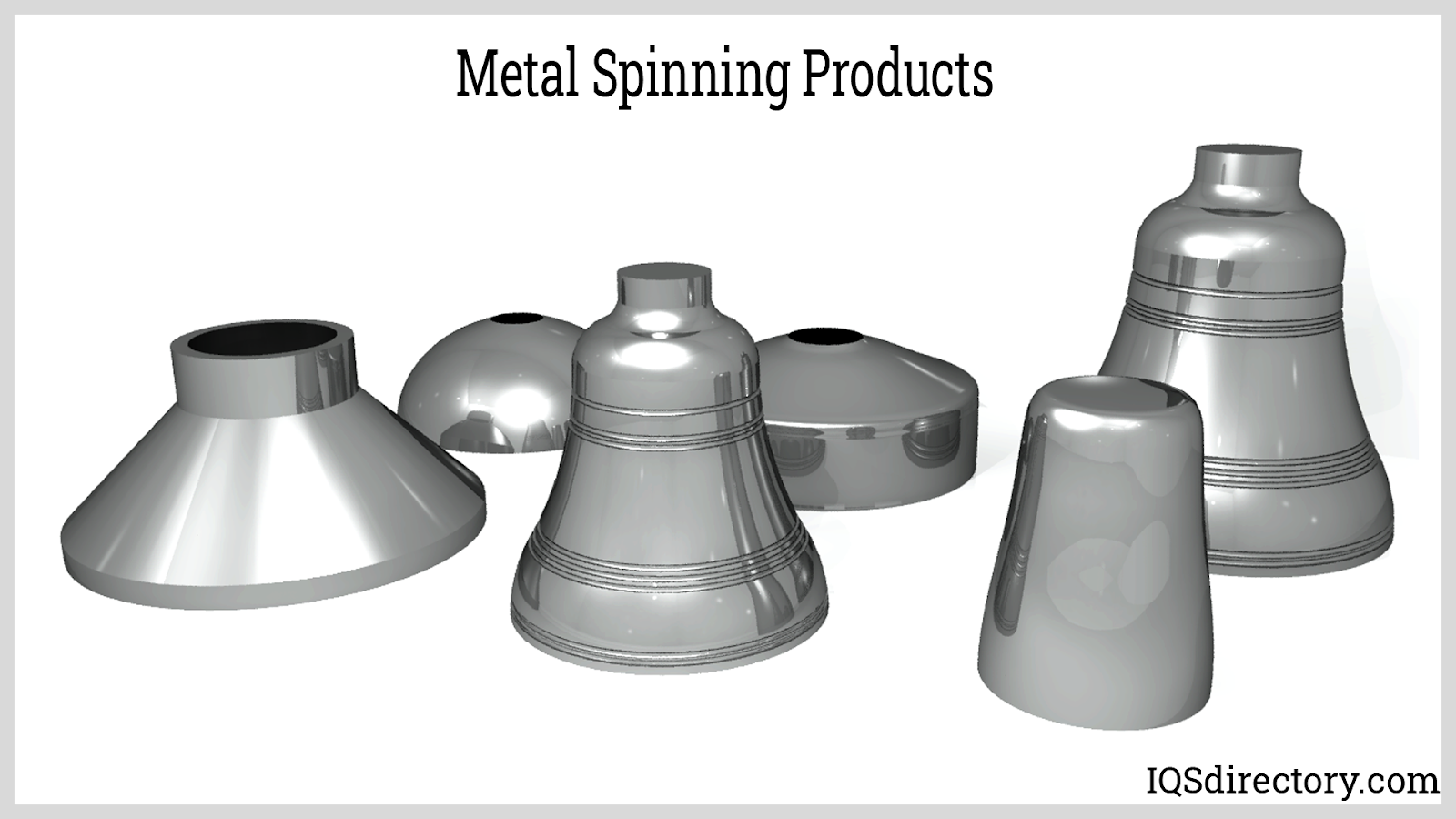

It is a cold working process, meaning the metal retains its ductility and tensile strength because it is not heated during forming. The finished products are round in cross section, lightweight and have a very smooth exterior and interior surface finish. Read More…

Century Metal Spinning provides high-quality aluminum & stainless steel metal spinning. Products can also be spun from titanium, copper, silver, gold & other materials. Examples of our products include rings, spheres, tubes, cylinders & tank heads. With our ISO 9001 & AS9100 certifications, we proudly serve aerospace, electronics, marine, military, pharmaceutical and a number of other industries.

Kryton Engineered Metals seamlessly crafts fabricated products. We are an ISO 9001:2015, full-service metal fab and spinning manufacturer with deep experience in air movement, lighting, vacuum, medical, food and beverage, agriculture, high voltage, and other markets. Kryton is consistently investing in new processes and equipment to grow with our expanding customer base. From a single piece to ...

At Elemet Group, our expertise revolves around providing comprehensive solutions in metal spinning, serving the diverse needs of clients across various industries. With decades of combined experience, a dedication to quality, and a customer-centric approach, we have positioned ourselves as a trusted leader in the field of metal forming. Our primary focus is on delivering a wide range of...

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

At Tallmadge Spinning & Metal Co., our expertise centers around providing comprehensive solutions in metal spinning, catering to the diverse needs of clients across various industries. With decades of collective experience and a steadfast commitment to excellence, we've positioned ourselves as a trusted leader in the metal forming industry. Our primary focus is on delivering a broad range of...

More Shear Spinning Companies

Like flow formed parts, shear spun products never require welding and are formed out of one preformed part called a blank, which is a flat piece of metal. The metal can either be punched with a hole in its middle, or it can be left completely solid. In the former case, this would result in a spun metal product with two openings - one above and one below.

In the latter case, the spun product would feature only one opening. Many different metals can be shear spun, including aluminum, steel, stainless steel, copper and titanium. Common shear spun products include rocket hose cones, gas turbine engines and dish aerials. The heating, cooling, architectural, food and beverage, agricultural, chemical and lighting industries also use the cone-shaped metal products that are formed by shear spinning.

The shear spinning process starts with manufacturing the blank, which is a preformed part made by deep drawing, stamping or press forming. It is a flat piece of metal that is engineered to ensure there is exactly enough material to form the final shape's dimensions. The blank is then sheared by rollers over a rotating mandrel. Higher force is needed from the spinning machine during this process in comparison to standard metal spinners.

While the diameter of the blank doesn't change, the thickness decreases depending on the angle of the mandrel and the gap between the rollers and the mandrel. This differs from standard metal spinning, where the thickness of the blank does not change. The wall thickness of the part is customized to certain stress requirements.

The finished product has smooth interior and exterior surfaces without any secondary manufacturing processes, including additional buffing, shining or polishing. No welding is needed during shear spinning and very little scrap metal is produced since the part is formed from a single blank. Different metals have varying degrees of spinnability, or the ability to undergo shear spinning without reaching maximum tensile strength.

Cold Headed Parts

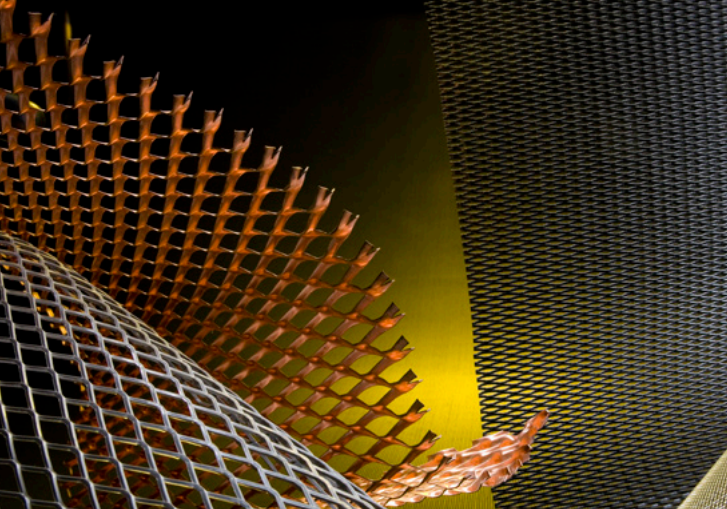

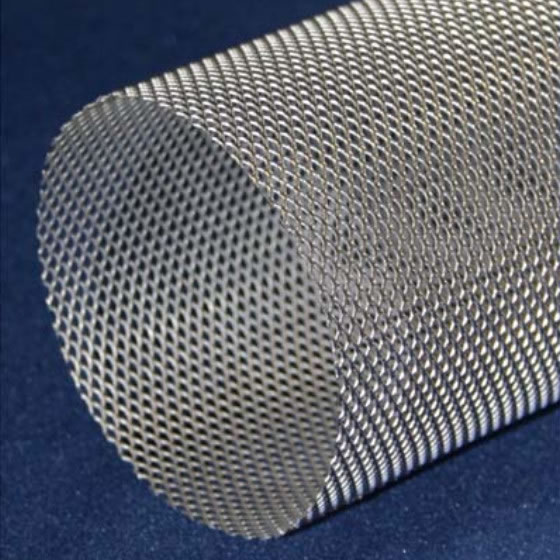

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

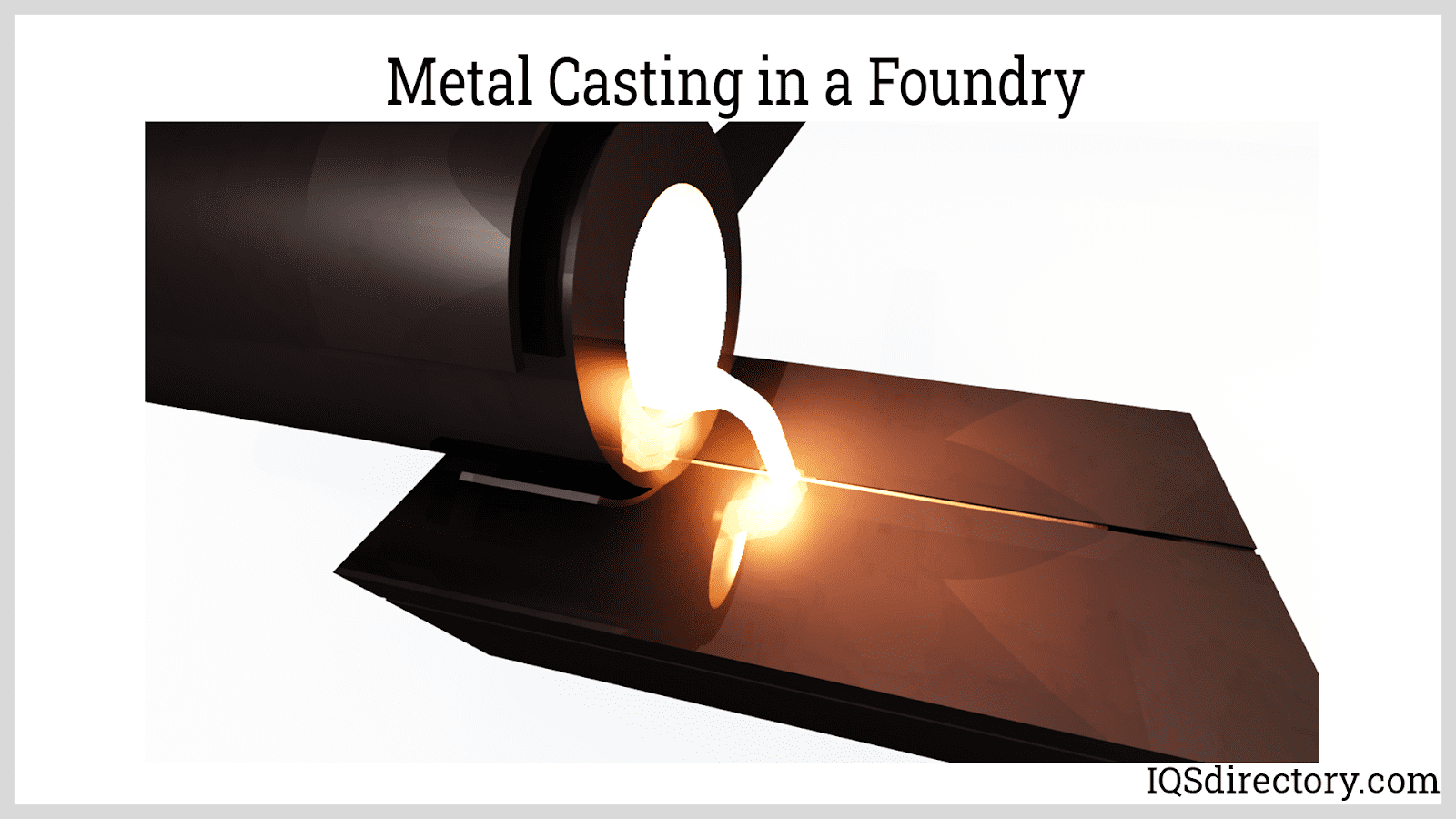

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services