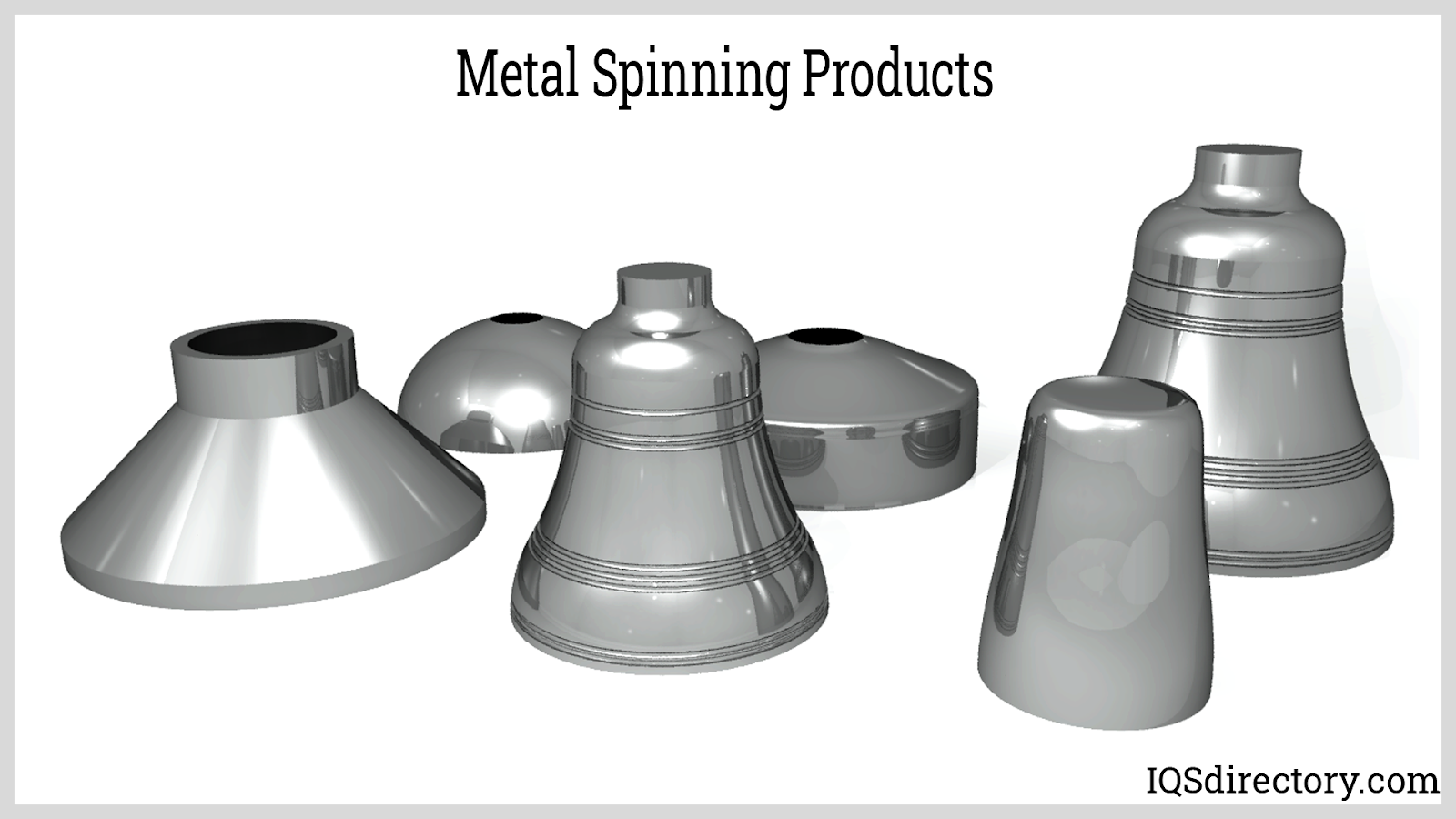

In the metal spinning process, a metal sheet is flattened into a disc and spun around a mandrel to create symmetrical, spherical shapes. Metal spinning creates shapes like hemispheres, cones, dishes, domes, cylinders, and flanges. Stainless steel bowls, satellite dishes, and brass instruments, including trumpets, tubas, cornets, and gas cylinders, are some products made by metal spinning. Read More…

For years, Precision Metal Spinning has proven to be a leader in innovation and quality within the metal spinning industry. Offering CNC and hand spinning, along with deep drawing capabilities, Precision Metal Spinning is ahead of the pack when it comes to size, precision, technology, and service to its clients in diverse fields such as medical, industrial and automotive.

Elyria Metal Spinning and Fab. Co, Inc. combines experience with up-to-date, state-of-the-art equipment to produce the best in aluminum, steel, brass, copper and stainless steel spun components up to 48" in diameter. The job shop offers hand, automatic and CNC spinning as well as several preparatory and secondary operations, allowing us to meet and exceed customer expectations every time. Visit...

Kryton Engineered Metals is an ISO 9002-certified, full-service metal spinning company. We provide high-quality custom aluminum spinning assembly as well as ready-made products and components. We know the art of spinning metal and can offer creative solutions to spin your part to your specifications. The bulk of our production is automated ensuring consistency and faster turn-around time.

Metalspun Products Company, Inc. is a manufacturer of precision metal spinnings and provides metal stamping, deep drawing, welding and anodizing services. Materials include aluminum, brass, bronze, copper, titanium and stainless steel. Short and long production runs are available. Serving the electronic, missile, laboratory, medical, food service, lighting and decorative industries for many years!

H & H Manufacturing & Engineering Inc. was started in 1966 by two brothers, Carl and Dave Howard. From its humble beginnings, H & H Mfg. has grown into one of the premier metal spinning shops in Southern California serving customers throughout the United States. Materials spun include various alloys of steel, stainless steel, aluminum, brass, and copper up to 0.125 in. thick. For more information ...

More Metal Spinner Companies

Different Approaches to Metal Spinning

The following are some methods that metal spinners may employ in their procedures.

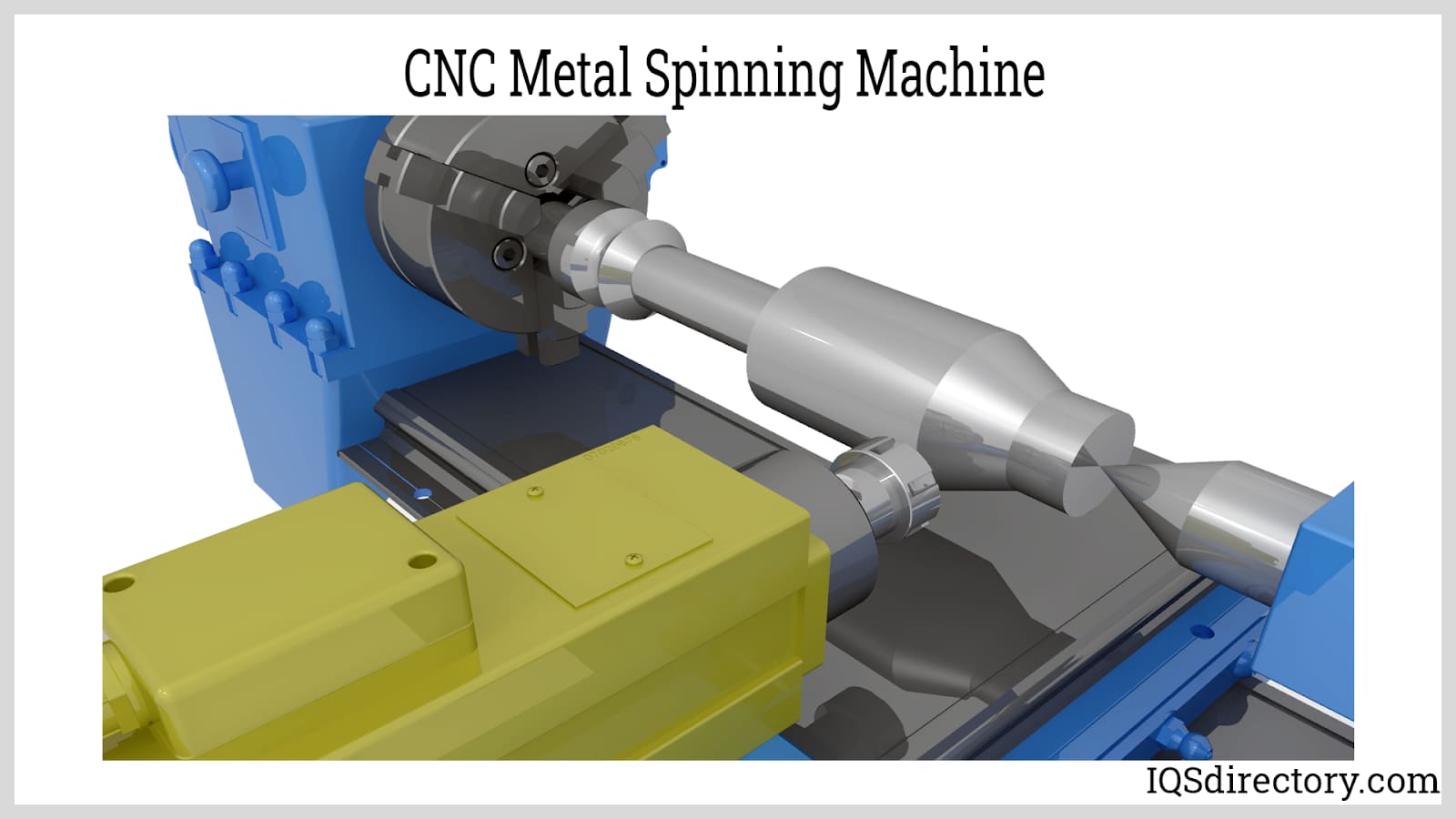

Computerized Numerical Control (CNC)

CNC metal spinning uses a lathe to automate and control the metal spinning procedure. Manual spinning and CNC metal spinning processes start similarly. First, the operator sets the workpiece on the CNC lathe drive and secures it with a pressure pad. Next, the settings for the forming process are programmed into the CNC machine. Finally, the workpiece is rotated and pressed against the mold when the lathe turns on. Like manual lathes, the CNC lathe's spinning force bends the metal piece into the mold's shape. CNC metal spinning is popular for its affordability, superior tensile strength, outstanding finishes, and refined grain structures.

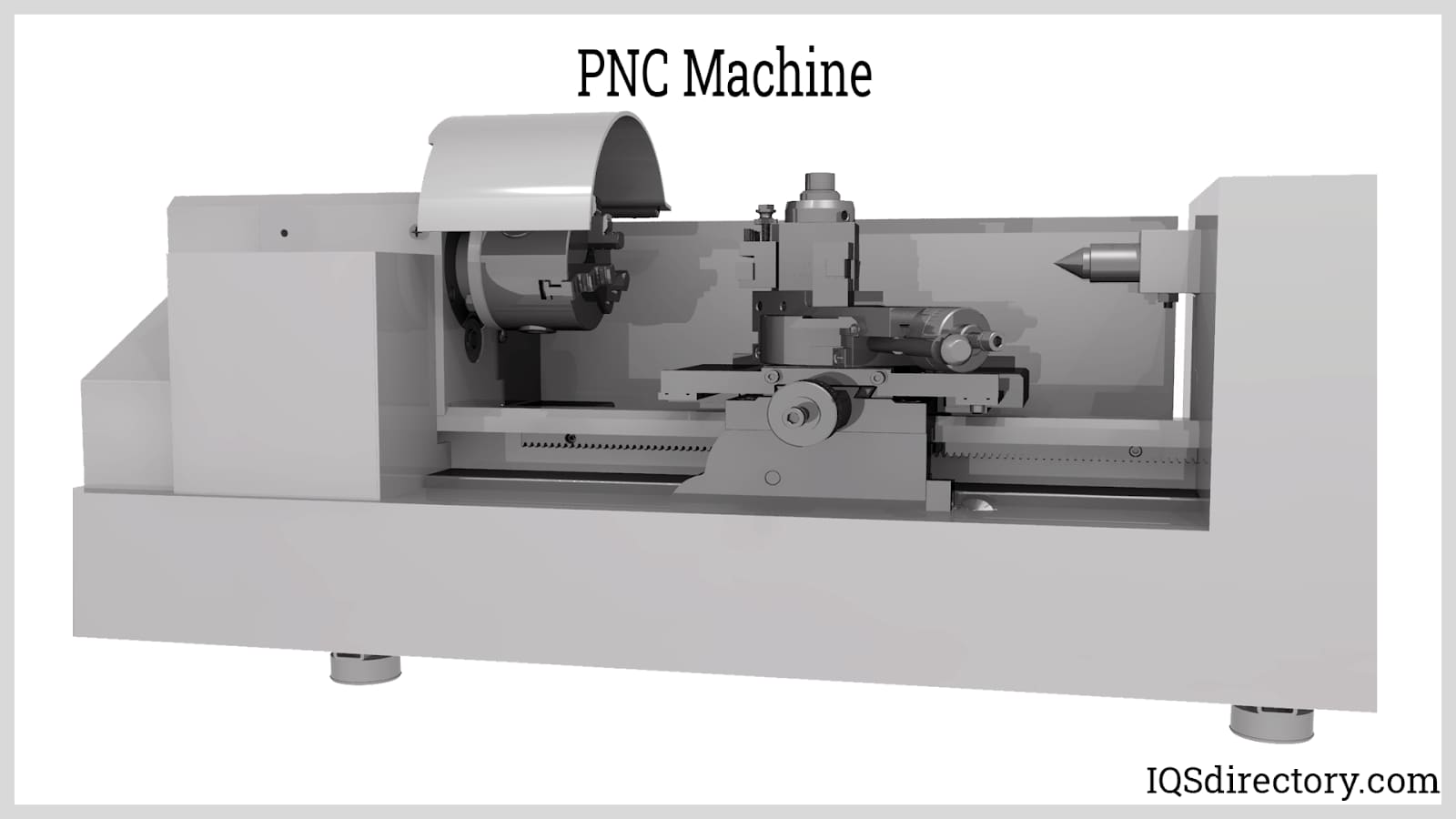

Playback Numerical Control (PNC)

With PNC metal spinning, the operator manually shapes the workpiece using a joystick. Eventually, the planned piece is created. The machine then remembers and repeats the adjustments, copying the operator's movements. PNC metal spinning makes high-volume production more effective. In the replay mode, the lathe copies the original part precisely by repeating the forming process as many times as necessary. Finally, the operator mounts the blank on the lathe, initiating the playback cycle.

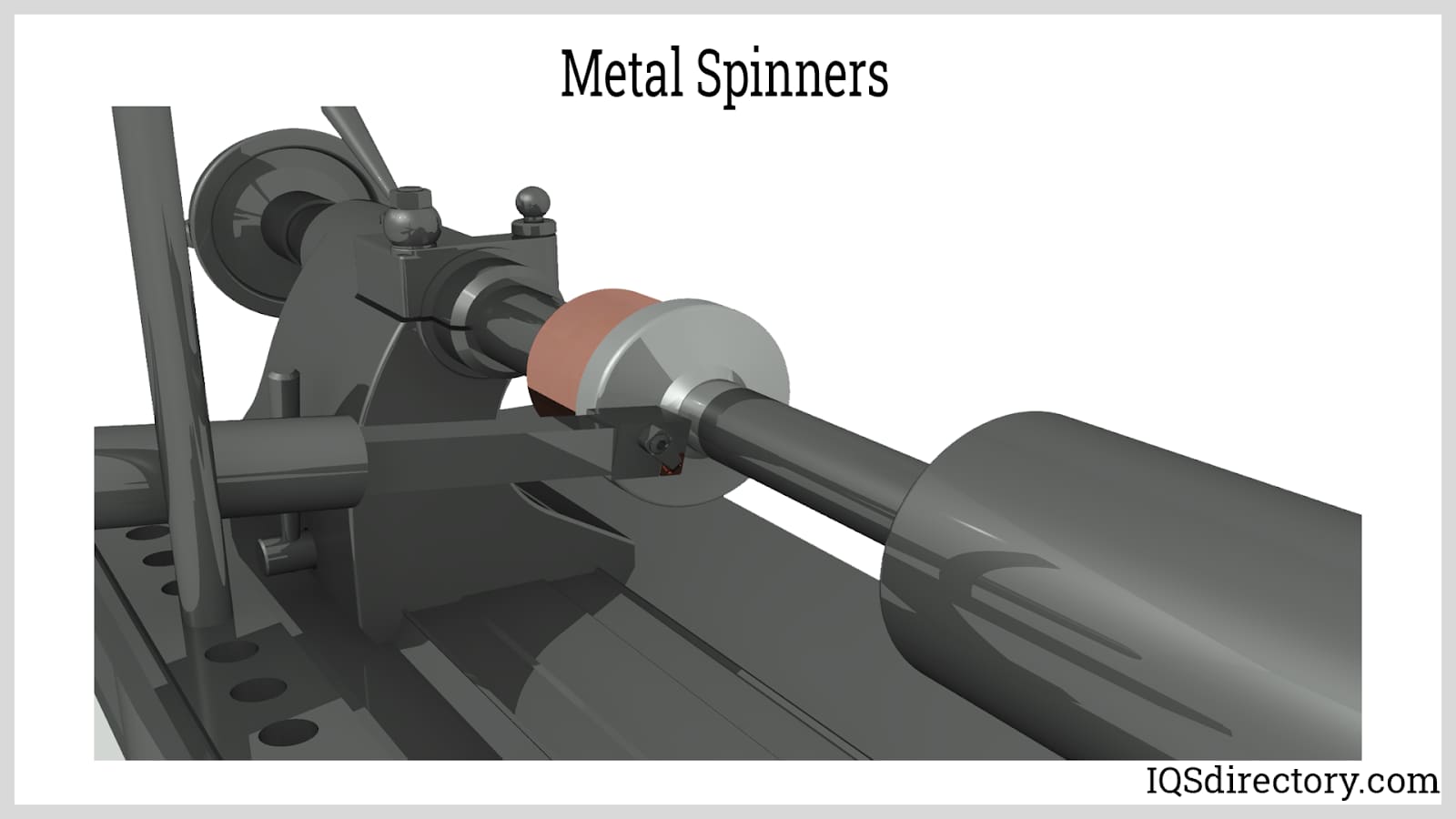

Hand Metal Spinning

The metal to be spun is placed on holders using a combination of talent and engineering. Then, a motor rotates the metal as a skilled individual molds it into the desired result.

The Metal Spinning Design Process

What is the object’s function?

Knowing the purpose of the workpiece will inform every step of the design process, and ensure final results genuinely meet the customer’s needs.

What material will work best for this metal spinning project?

The material used influences the way metal is spun. Designs could vary from being a millimeter thin or an inch thick. Manufacturers and clients should work together to choose the best material for the project.

Carefully consider the diameters.

It is common for metal-spun objects to be rolled into tubes. Metal spun objects have different thicknesses. Large corner radii will wear down the material slower than small corner radii. Larger corners are stronger and more cost-effective than tight corner radii.

Think About the Dimensions.

It’s crucial to plan out the required dimensions. Saving even a bit of material can result in huge financial savings for the project.

Indicate Tolerances

A metal-spun product doesn’t require a constant thickness throughout. However, the designer must specify an acceptable deviation from the true value.

Challenges faced by Metal Spinning Manufacturers

Shape and Size

In conventional or modern spinning processes, size and shape variaitons are limited. This makes it simpler to produce axially symmetrical and concentric forms. Shapes with dished heads, stepped edges, parabolas, funnels, cones, and hemispheres are easier to spin. Additionally, the diameter of the manufactured components is constrained. Using metal spinning to create irregular shapes is a nightmare.

Production constraints

Due to production constraints, rollers and spoons are popular tools when manufacturing metal spinning goods. Manufacturers must create unique tool components for bespoke productions to meet the necessary application requirements. This can entail creating a new mandrel. It would be pointless financially to develop all of this machinery and equipment to create a small number of products. It’s more cost effective to create large quantities of products for customized productions.

Errors

Errors are a part of every forming process, including the process of spinning metal. When a dent or crack develops during this process, it cannot be repaired. Repairing tiny flaws or imperfections can be costly. Additionally, before beginning the spinning process, a hardened metals must be subjected to heat treatment.

Choosing the Right Metal Spinners Supplier

To make sure you have the most constructive outcome when purchasing Metal Spinners from a Metal Spinners Company, it is important to compare at least 5 Manufacturers using our list of Metal Spinners companies. Each Metal Spinners Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Metal Spinners business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Metal Spinners companies with the same quote.

Cold Headed Parts

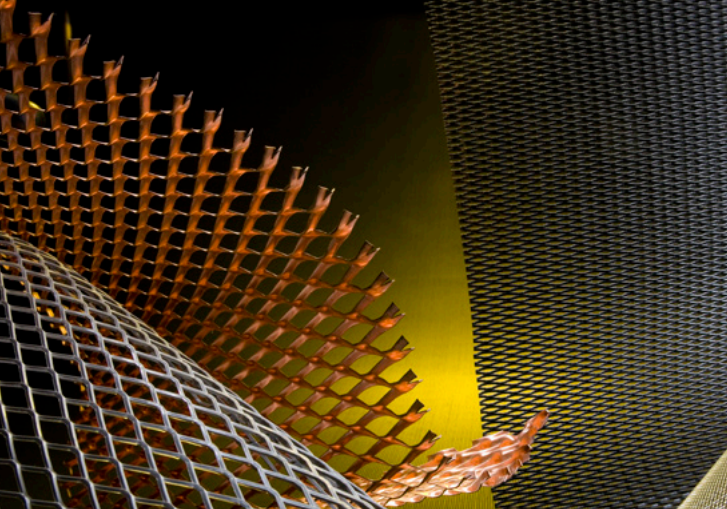

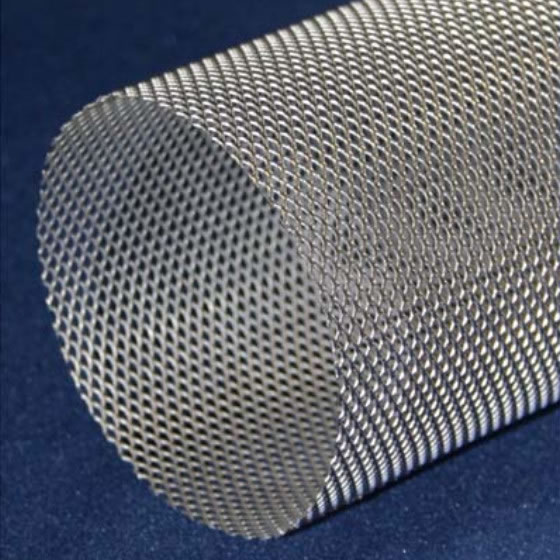

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services