This is why aluminum is found in such a wide range of applications from cars and boats to construction and household items. Read More…

Century Metal Spinning provides high-quality aluminum & stainless steel metal spinning. Products can also be spun from titanium, copper, silver, gold & other materials. Examples of our products include rings, spheres, tubes, cylinders & tank heads. With our ISO 9001 & AS9100 certifications, we proudly serve aerospace, electronics, marine, military, pharmaceutical and a number of other industries.

Kryton Engineered Metals seamlessly crafts fabricated products. We are an ISO 9001:2015, full-service metal fab and spinning manufacturer with deep experience in air movement, lighting, vacuum, medical, food and beverage, agriculture, high voltage, and other markets. Kryton is consistently investing in new processes and equipment to grow with our expanding customer base. From a single piece to ...

At Elemet Group, our expertise revolves around providing comprehensive solutions in metal spinning, serving the diverse needs of clients across various industries. With decades of combined experience, a dedication to quality, and a customer-centric approach, we have positioned ourselves as a trusted leader in the field of metal forming. Our primary focus is on delivering a wide range of...

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

At Tallmadge Spinning & Metal Co., our expertise centers around providing comprehensive solutions in metal spinning, catering to the diverse needs of clients across various industries. With decades of collective experience and a steadfast commitment to excellence, we've positioned ourselves as a trusted leader in the metal forming industry. Our primary focus is on delivering a broad range of...

More Spun Aluminum Companies

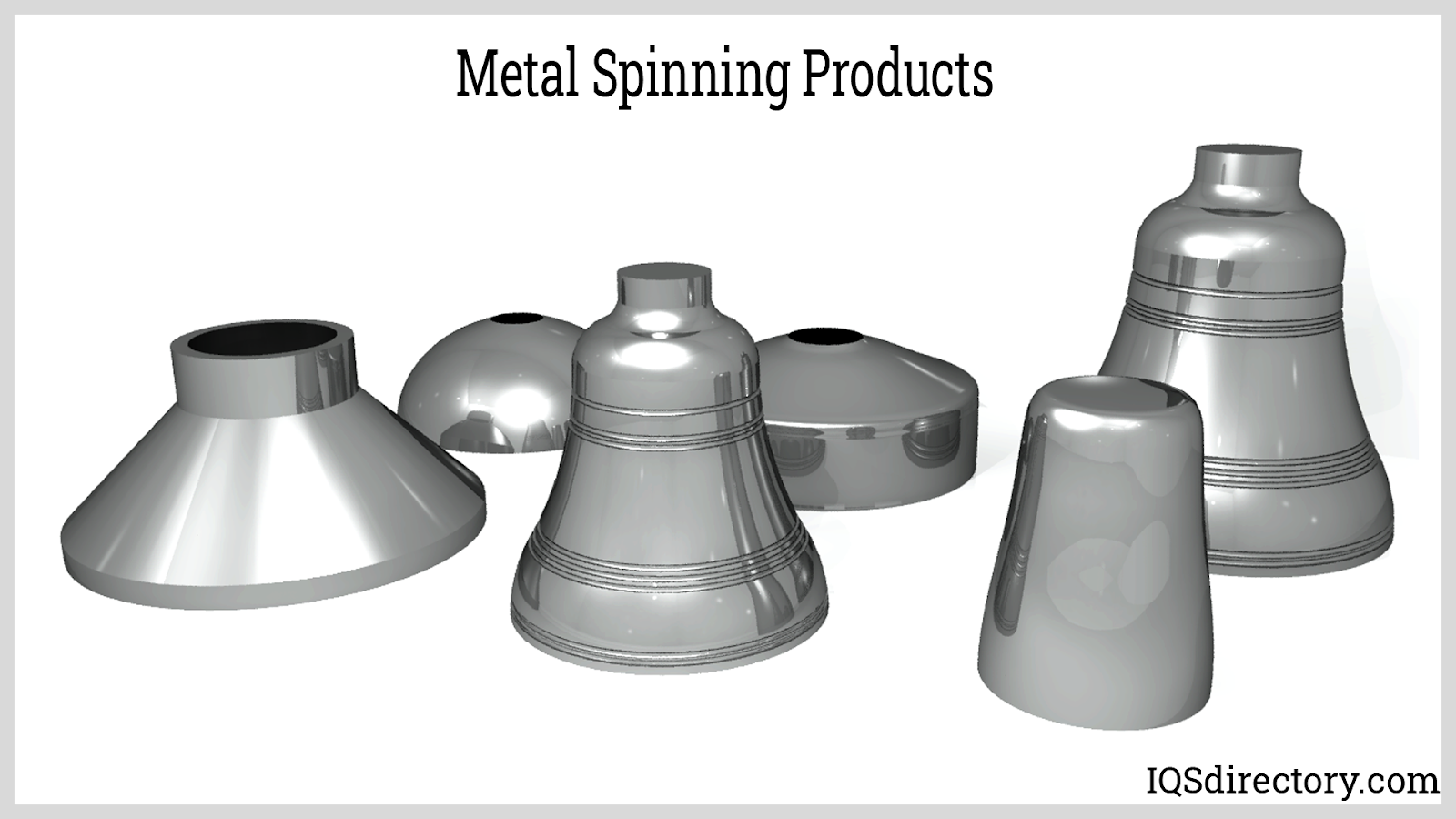

There are also a large number of ways in which aluminum can be manufactured in order to produce products. One of the lesser known ways is a process called metal spinning and spun aluminum is made from this process which provides products such as scuba tanks or CO2 cartridges.

The overall process of metal spinning is a relatively easy concept to grasp as the metal typically starts in a disc form and then put into a lathe. From here a shaping tool is used to create the look of the final product. This tool is pushed up against the disc while the other side of the disc is being pushed into the tool, this forces the metal to form a shape around the tool.

This action is what creates the final product. In order for this process to be effective, the metal must have high ductility meaning that it must be able to be reshaped when a pulling stress is placed upon it. And aluminum is one of the most common metals for this type of process as it has a high ductility and as mentioned earlier is an abundant and advantageous metal.

The metal spinning process itself is also a pretty inexpensive process, especially when comparing it to other methods of metalworking as it can be performed pretty quickly. In addition, any design changes can be easily and inexpensively made as well. Spun aluminum is often used when creating prototypes for this very reason.

For any further questions on metal spinning or on spun aluminum specifically, we encourage you to seek out a trusted and experienced spun aluminum manufacturer who will be able to diagnose your application and find the best possible solution based on your unique requirements and needs.

Cold Headed Parts

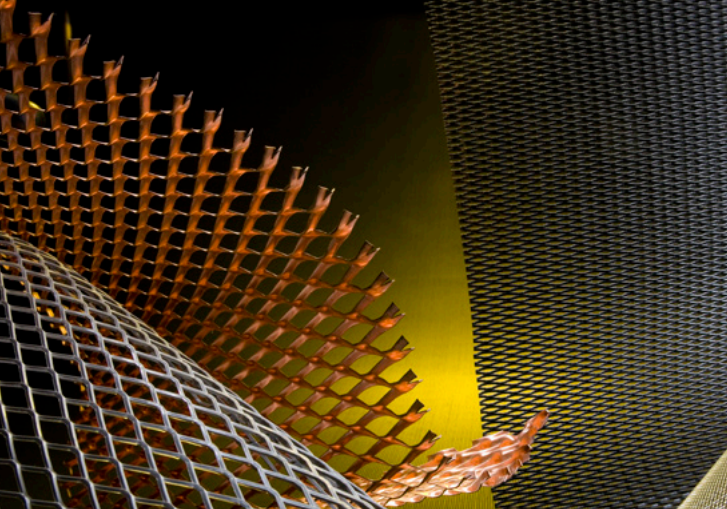

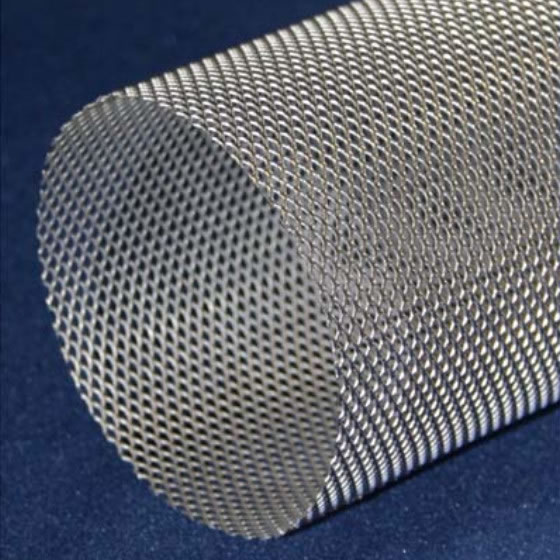

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

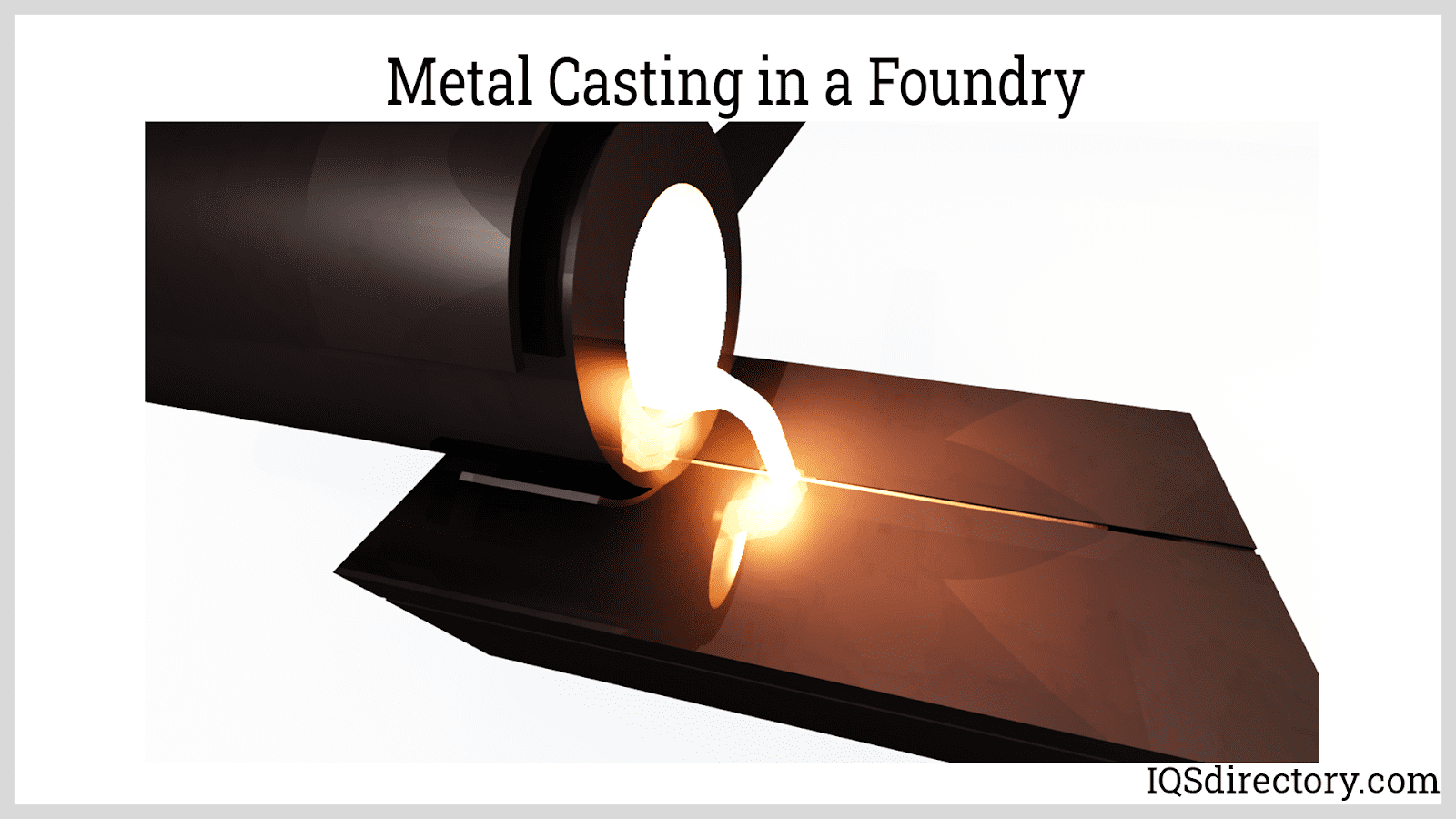

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services