It allows variation in wall thickness of its products, which are hollow and tubular or rotationally symmetric products. Flow forming helps manufacturers meet complex design specifications and allows for a wider range of dimensional flexibility. Read More…

Century Metal Spinning provides high-quality aluminum & stainless steel metal spinning. Products can also be spun from titanium, copper, silver, gold & other materials. Examples of our products include rings, spheres, tubes, cylinders & tank heads. With our ISO 9001 & AS9100 certifications, we proudly serve aerospace, electronics, marine, military, pharmaceutical and a number of other industries.

Kryton Engineered Metals seamlessly crafts fabricated products. We are an ISO 9001:2015, full-service metal fab and spinning manufacturer with deep experience in air movement, lighting, vacuum, medical, food and beverage, agriculture, high voltage, and other markets. Kryton is consistently investing in new processes and equipment to grow with our expanding customer base. From a single piece to ...

At Elemet Group, our expertise revolves around providing comprehensive solutions in metal spinning, serving the diverse needs of clients across various industries. With decades of combined experience, a dedication to quality, and a customer-centric approach, we have positioned ourselves as a trusted leader in the field of metal forming. Our primary focus is on delivering a wide range of...

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

At Tallmadge Spinning & Metal Co., our expertise centers around providing comprehensive solutions in metal spinning, catering to the diverse needs of clients across various industries. With decades of collective experience and a steadfast commitment to excellence, we've positioned ourselves as a trusted leader in the metal forming industry. Our primary focus is on delivering a broad range of...

More Flow Forming Companies

Many metals, including stainless steel, titanium, copper, aluminum, nickel and brass are subjected to flow forming, which produces products for the aerospace, automotive, nuclear, chemical and petrochemical industries. Flow forming offers many benefits, including the reduced need for welding, shorter length of stock shapes and tighter design tolerances. Though this process is energy saving, the workpiece is subjected to a great amount of friction and deformation.

Flow forming is a cold working process, meaning the metals being formed are shaped at or around room temperature, which ensures that they retain their tensile strength and ductility. While flow forming is able to produce any shape that standard metal spinning can, it specializes in producing automotive wheels for several different kinds of vehicles.

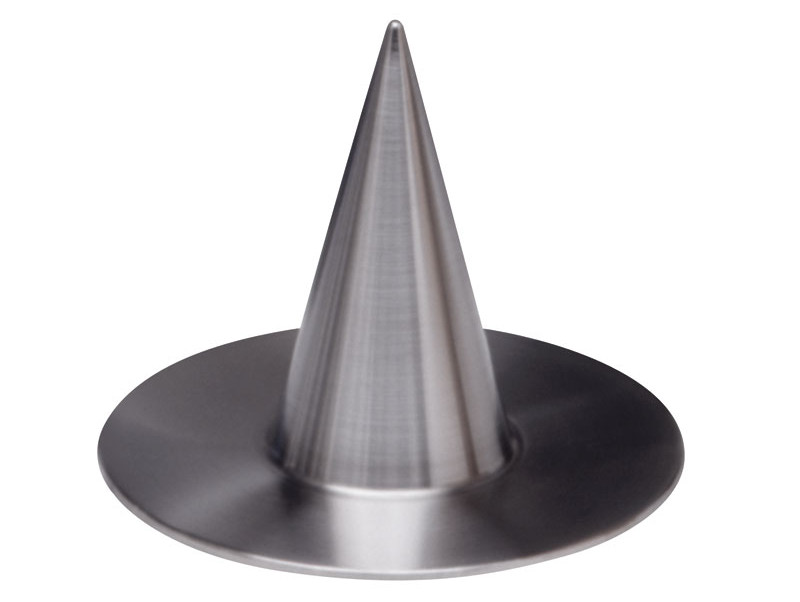

There is a key difference between flow forming and standard metal spinning. Conventional metal spinning uses a thin blank and produces a finished part from the diameter of that blank, while flow forming produces the finished shape by working from the thickness of the starting blank, which creates a part thinner than the original starting blank. The blank, or preformed metal part, is a flat metal disc, which can be stamped with a hole or left whole, that is clamped down.

It is spun on a lathe while rollers apply pressure, forcing it to take the mandrel's shape. The rollers extrude the cross sectional area of the blank's wall thickness. The thickness of the finished part is determined by a gap that is maintained between the mandrel and the rollers. The flow forming process is used in conjunction with swaging, flattening, bending and machining. It produces a smooth, complex part without any chipping or unwanted deformation.

Cold Headed Parts

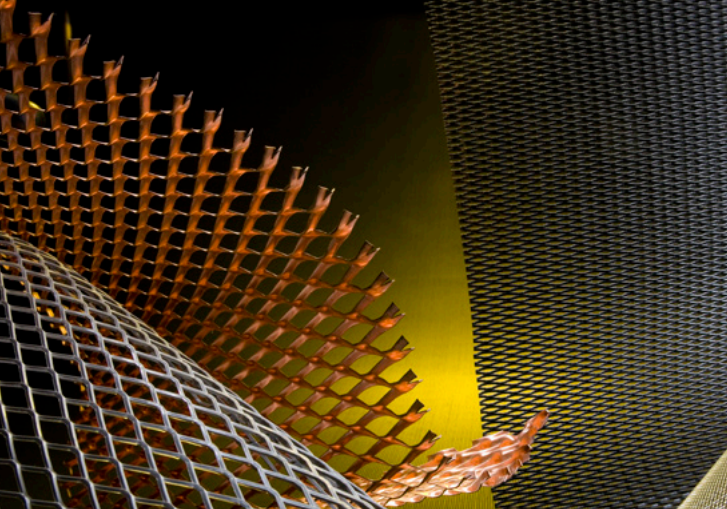

Cold Headed Parts Expanded Metals

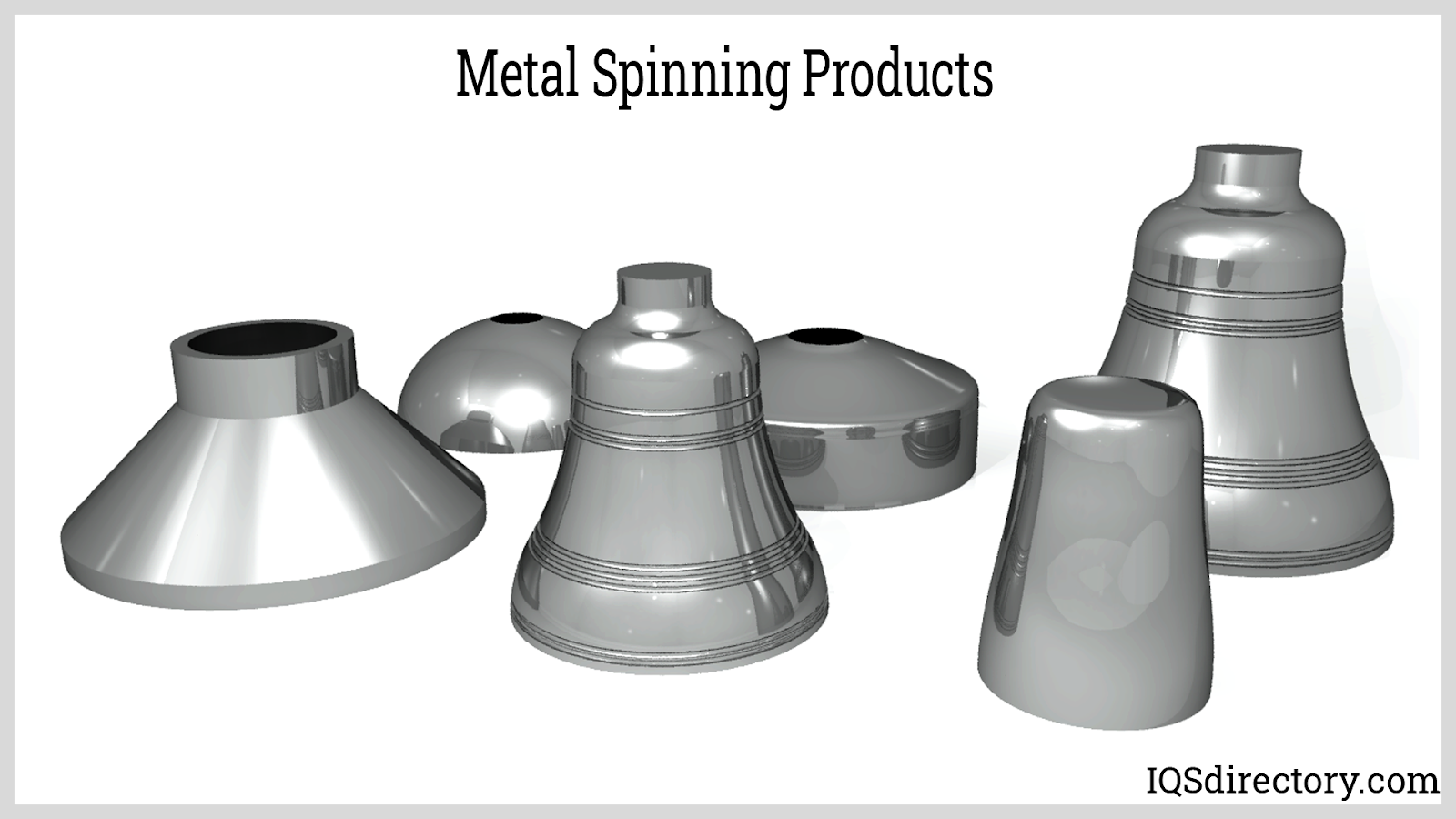

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

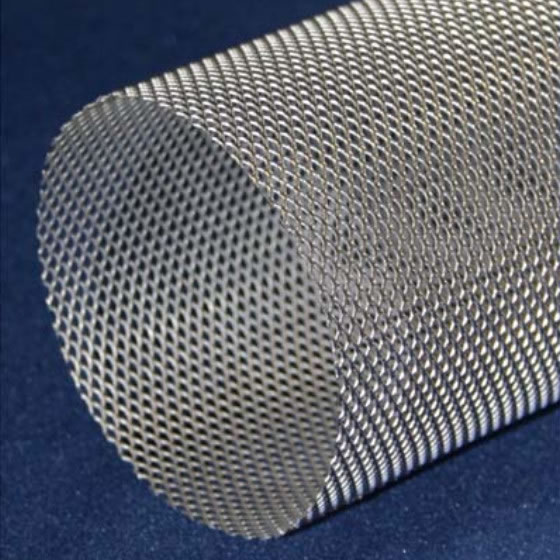

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

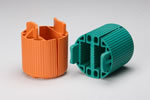

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services