Hydroforming is an efficient and specialized molding process that uses highly pressurized fluid to form metals. Hydroforming’s metal fabrication and forming process can shape steel, stainless steel, copper, aluminum, and brass. The ability to preserve high-quality surfaces for finishing and seamless bonding are some advantages of hydroforming. Hydroformed parts have a higher stiffness-to-weight ratio, are more affordable per unit, and are lighter than conventional metal stamped and welded parts. Hydroforming can also produce components in a single step, saving time, resources, and materials. Read More…

Century Metal Spinning provides high-quality aluminum & stainless steel metal spinning. Products can also be spun from titanium, copper, silver, gold & other materials. Examples of our products include rings, spheres, tubes, cylinders & tank heads. With our ISO 9001 & AS9100 certifications, we proudly serve aerospace, electronics, marine, military, pharmaceutical and a number of other industries.

Kryton Engineered Metals seamlessly crafts fabricated products. We are an ISO 9001:2015, full-service metal fab and spinning manufacturer with deep experience in air movement, lighting, vacuum, medical, food and beverage, agriculture, high voltage, and other markets. Kryton is consistently investing in new processes and equipment to grow with our expanding customer base. From a single piece to ...

At Elemet Group, our expertise revolves around providing comprehensive solutions in metal spinning, serving the diverse needs of clients across various industries. With decades of combined experience, a dedication to quality, and a customer-centric approach, we have positioned ourselves as a trusted leader in the field of metal forming. Our primary focus is on delivering a wide range of...

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

At Tallmadge Spinning & Metal Co., our expertise centers around providing comprehensive solutions in metal spinning, catering to the diverse needs of clients across various industries. With decades of collective experience and a steadfast commitment to excellence, we've positioned ourselves as a trusted leader in the metal forming industry. Our primary focus is on delivering a broad range of...

More Hydroforming Companies

Types of Hydroforming

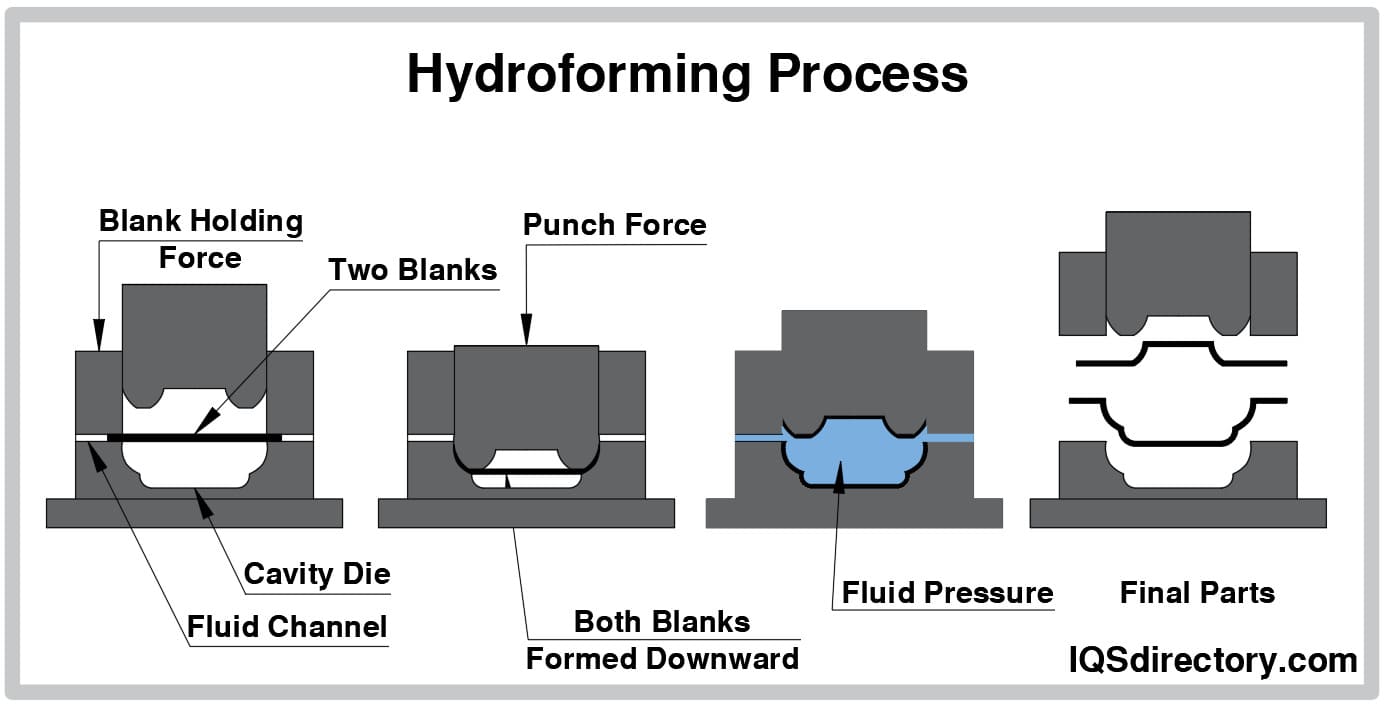

Sheet Hydroforming

When shaping sheet metal against a single, unmatched tool, sheet hydroforming uses a pressurized hydraulic fluid in a flexible diaphragm. Presses for sheet hydroforming can combine or even replace various metal forming techniques, such as progressive die forming, press brake forming, classic draw forming, rubber pad forming, and more. Additionally, by combining several operations into a single cycle, these machines can do away with secondary finishing procedures like welding, annealing, or polishing.

Fluid Cell Sheet Hydroforming

Fluid Cell sheet hydroforming machines are the best choice for creating parts with intricate bends and curves. First, the blank sheet material is stacked atop a single fixed-form block or tool resting unsecured on the lower plate or working surface during a fluid cell cycle. Next, a hydraulic fluid-filled compressed diaphragm is extended across the tool and blank, expanding as it applies equal pressure to every place inside the chamber. As a result, the part is almost net-shaped and needs little to no further finishing.

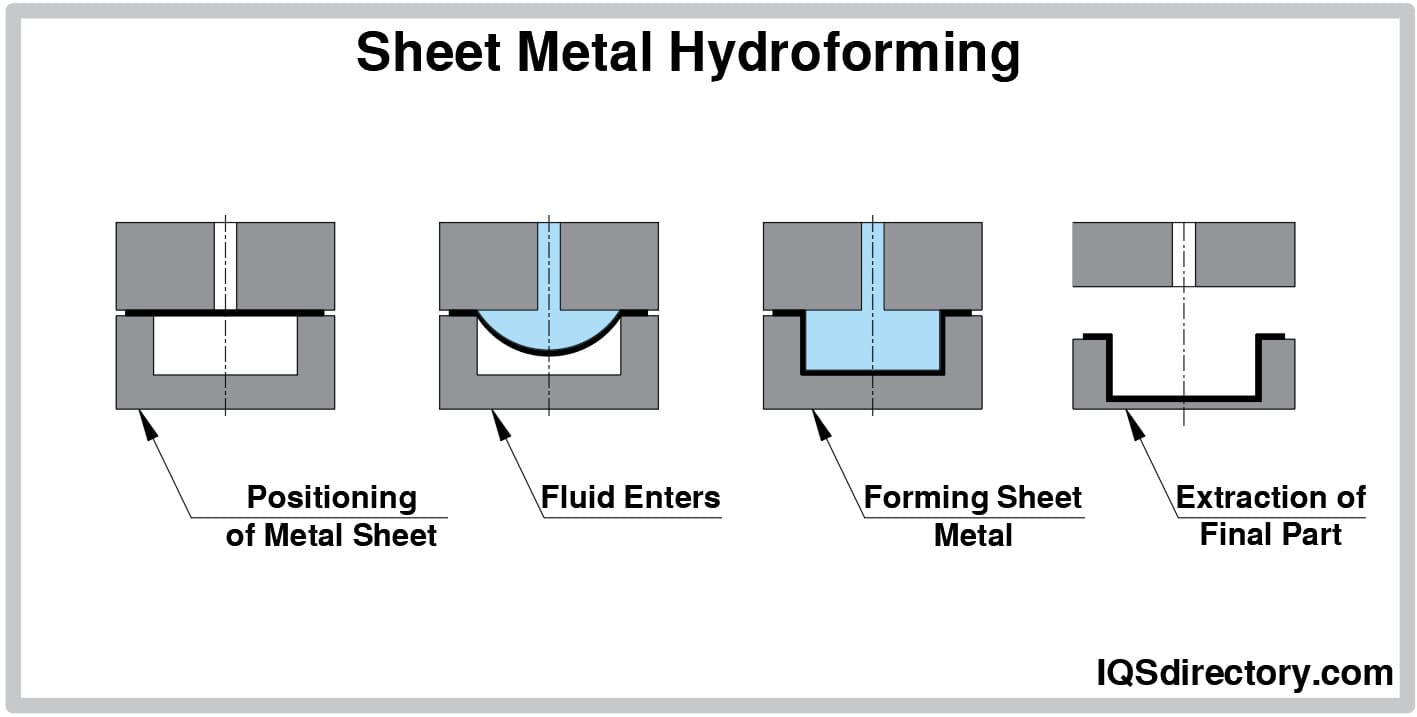

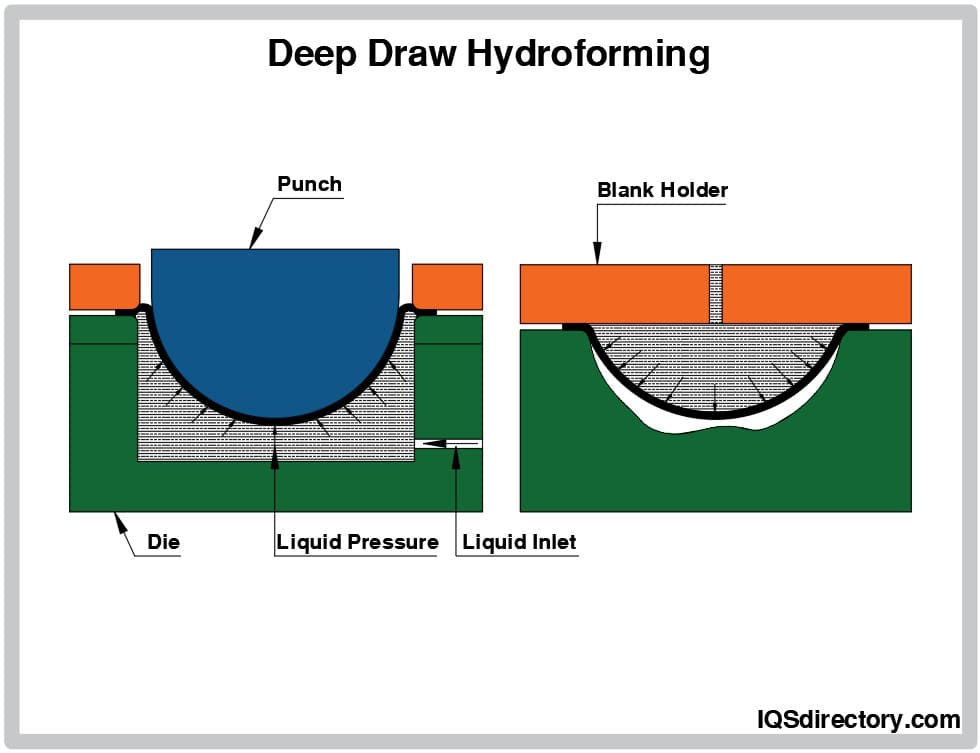

Deep Draw Sheet Hydroforming

Sheet metal is stretched and bent into the correct shape during deep draw hydroforming. A tool is pressed down on the sheet metal to force it into a die cavity in a predetermined shape. The metal takes on the shape of a cup because of the tensile force. The deep drawing process can begin starting with a blank, a blank holder, a punch, and a die. Over the die, the blank holder receives the blank or piece of sheet metal. The desired part's shape can be seen in the hollow. The part is then drawn, or bent/stretched, into the required shape using a punch that descends onto the blank without weakening it. The deep draw is frequently applied to ductile metals like mild steel, copper, and aluminum.

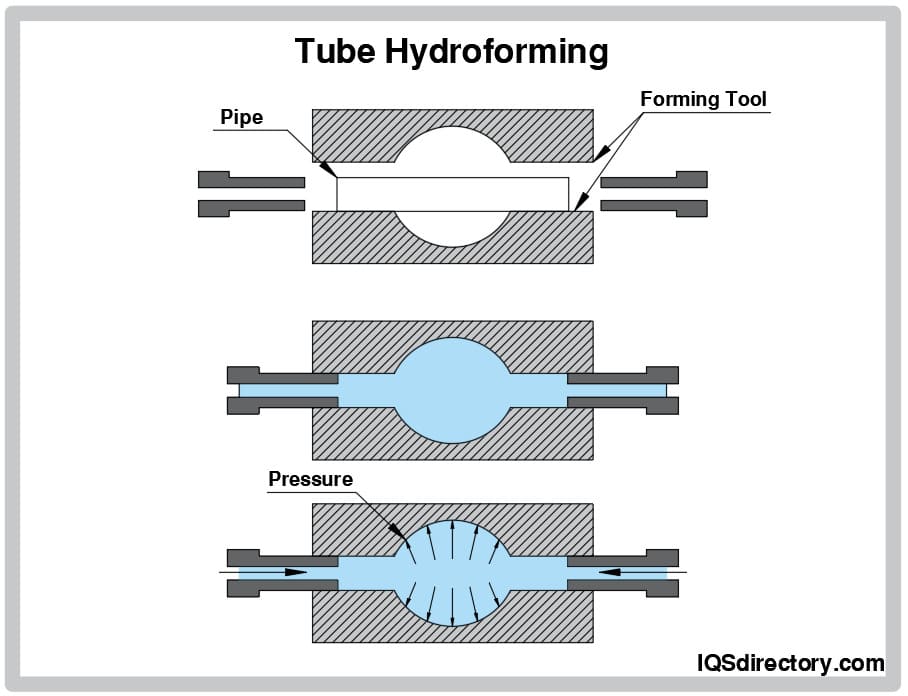

Tube Hydroforming

Hydroforming can also form tubular components like brackets for bicycle frames or pipe fittings. Internal pressure and axial force may be applied to the tube; this induces compressive stress in one direction, which causes the tube's elements to deform without thinning and delays tearing. Hydroforming can form many parts at a low cost using specially-built forming equipment.

Steps to Tube Hydroforming

The raw tube is loaded into the tube bender if the shape has bends that don't follow a straight line. This causes the tube to bend, providing it with the required curvature to fit into the dies. The pre-form press is often used to insert the tube into the die. After that, the liquid enters the die. The hydroforming press receives the portion next. The liquid inside the tube will be pressurized by this press, giving the component its final shape and appearance. The thrust actuators' actions may occasionally aid in forming the tube. If a parts wash is necessary to achieve precise laser cutting or stenciling, it is applied to freshly hydroformed components.

Benefits of Hydroforming

- Hydroforming allows the metal tube to be formed into lengthy, complicated forms with fewer welds. This lowers resistance and increases airflow effectiveness compared to traditional methods that require joining many separate metal sections together.

- The entire procedure is completed quicker, often in just 20 seconds, from filling the blank tube to unloading the final product. This allows a seamless assembly of exhaust chain components to be created.

- While metal is under tremendous pressure inside the tool, the computer regulates it within ten-thousandths of an inch. This results in very high precision.

- By repeating the procedure, one can eliminate waste from dented or unintentionally bent pieces and use less material because the sections are combined into one assembly.

- Thinner walls can obtain the necessary stiffness during hydroforming, resulting in lighter products. This was not achievable in earlier procedures.

- Hydroforming allows for creating complex structures out of pre-bent tubes that can even include inlet and exit openings.

- Due to fewer sections and the removal of the burring and punching procedures, the number of tools can be considerably decreased.

Choosing the Proper Hydroforming Company

To make sure you have the most constructive outcome when purchasing Hydroforming from a Hydroforming Company, it is important to compare at least 4 or 5 Manufacturers using our list of Hydroforming companies. Each Hydroforming Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Hydroforming business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Hydroforming companies with the same form.

Cold Headed Parts

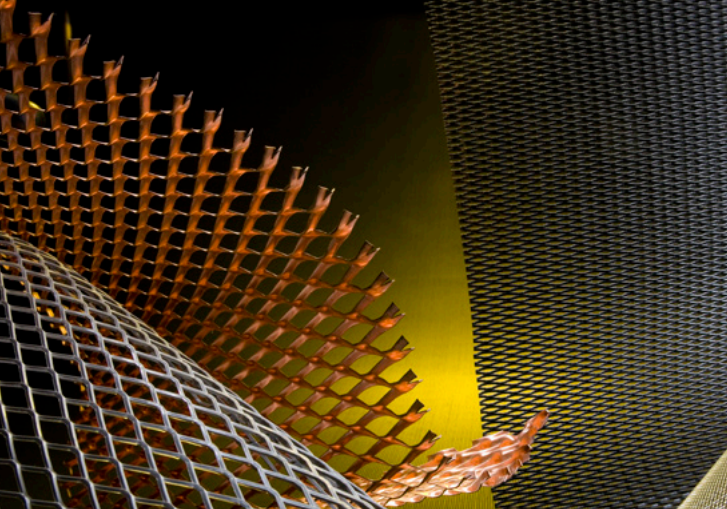

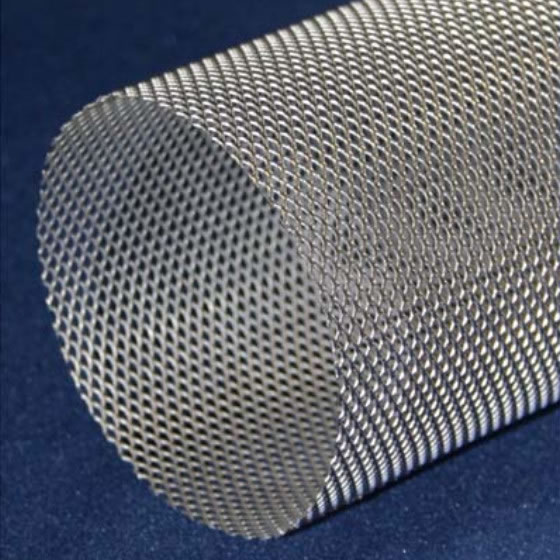

Cold Headed Parts Expanded Metals

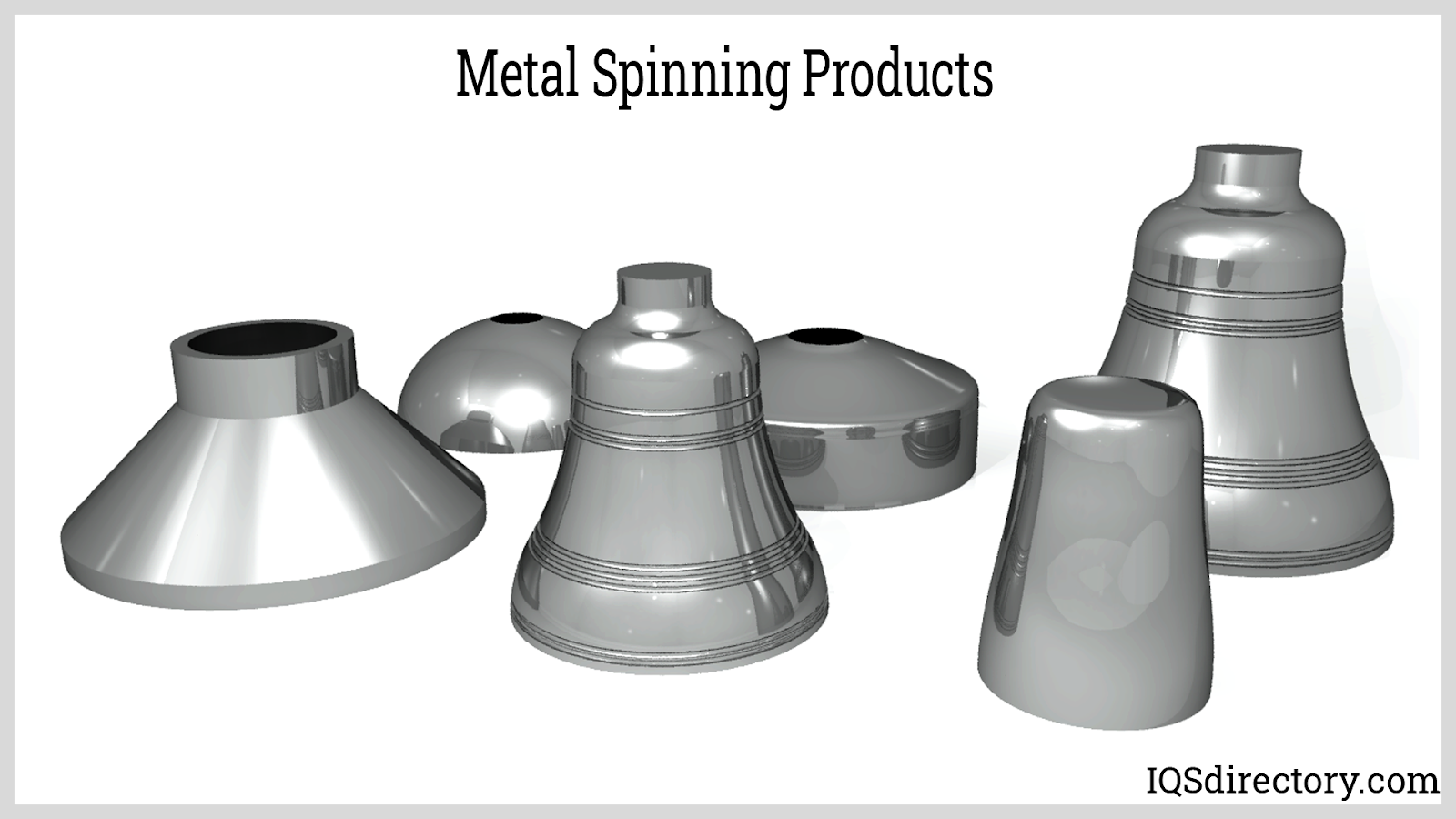

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

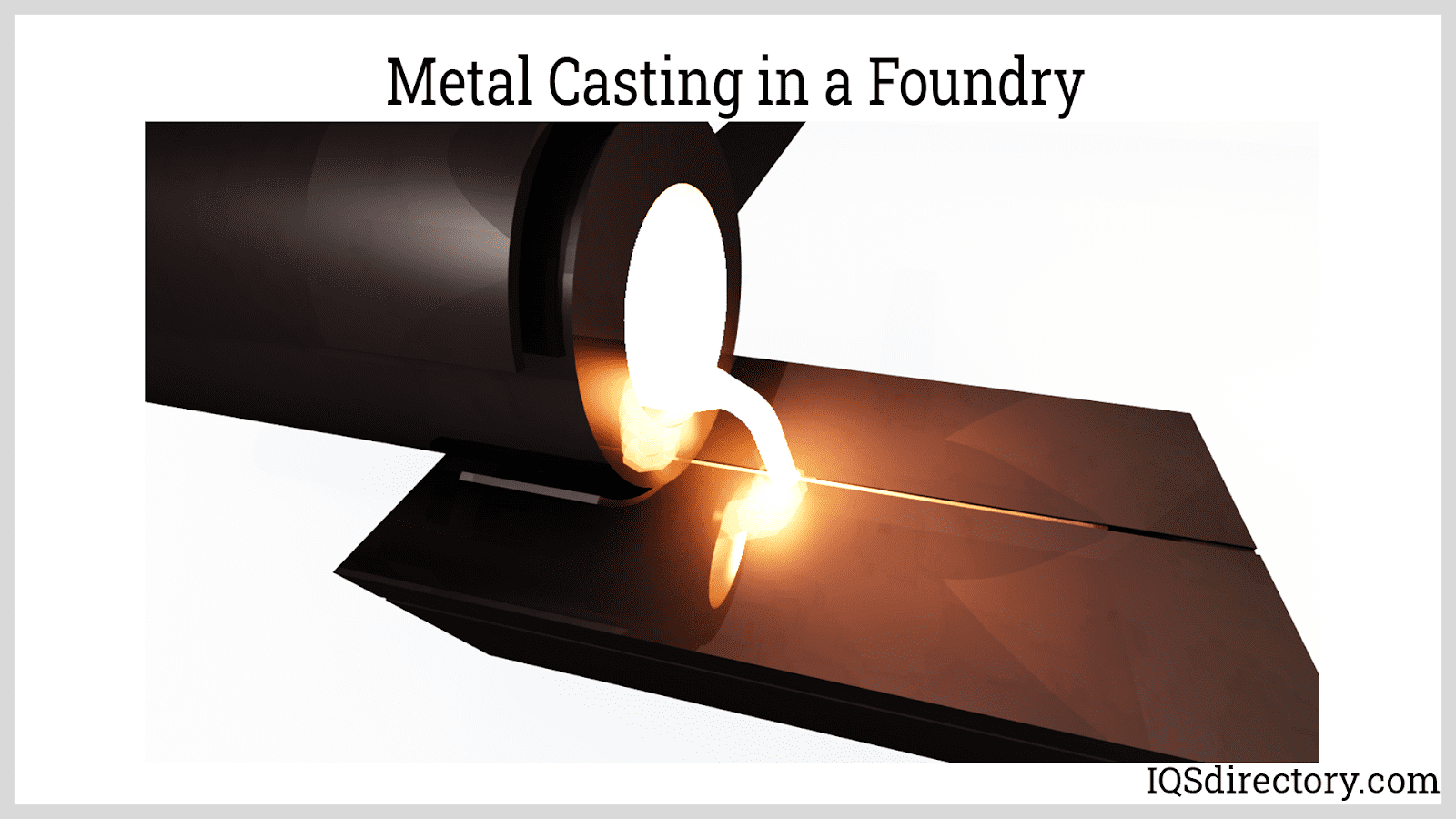

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services